Why it matters

Why it matters

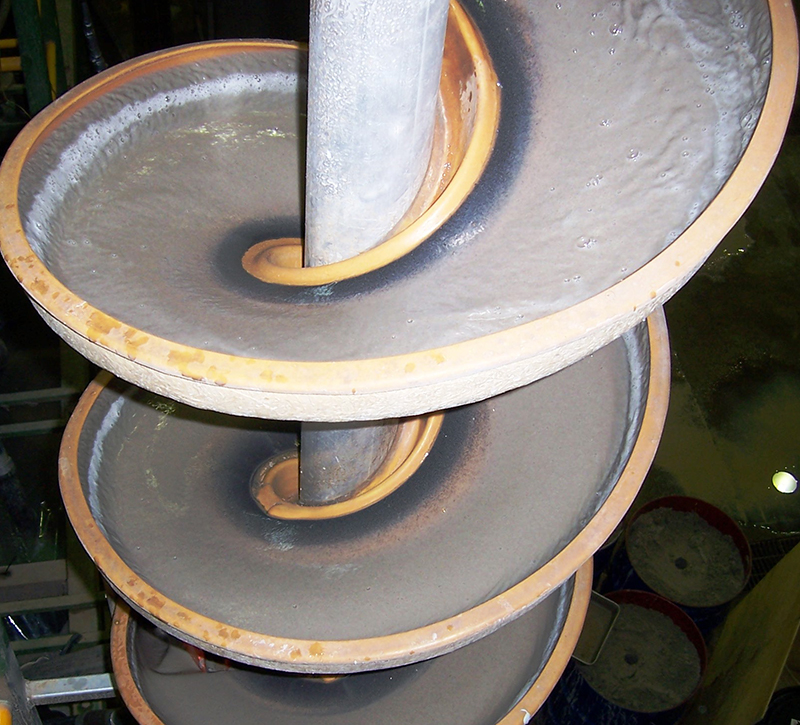

Chrome Spiralinto Recovery

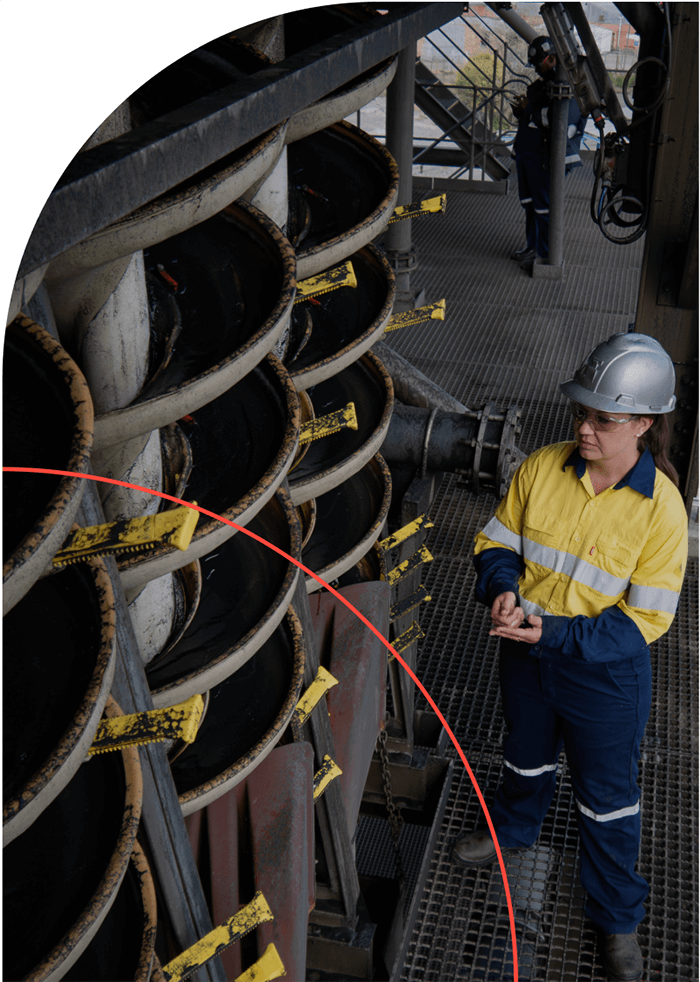

As the global leader in chrome production, South Africa faces the pressing challenge of reliability in its fines processing operations. The industry demands robust equipment capable of enduring the abrasive nature of chrome extraction. Our advanced spirals excel in durability, efficiency, and reliability, outperforming competitors while maximising production in a smaller space. Embrace the future of chrome mining with our promise of enhanced longevity and profitability.

The Challenge

The Challenge

Tough onRough

Chromite processing faces many unique challenges arising from the high particle densities encountered, the erosive nature of the ore and the frequent presence of very fine particles that lead to clogging and reduced spiral efficiency. When these are combined with ore variations and product quality challenges an innovative approach to spiral design is needed to improve and maximise separation efficiency. Mineral Technologies embraces these challenges and produces the world-leading spiral designs you need for your operation.

Our Solution

Our Solution

MT Spirals

Our advanced spirals are engineered to provide consistent and reliable performance in chrome mining operations. Unlike traditional solutions that may falter under the abrasive conditions of chrome extraction, our spirals excel, offering unparalleled durability and efficiency. With our spirals, mining operators can trust in a reliable solution that minimises downtime and maximises productivity.

With over 40 spiral variations, speak to us about which spiral works for you, and kick things off with testwork in our own mineral lab.

Both our Australian and South African facilities are ISO 9001 certified.

The Advantages

The Advantages

Less is more

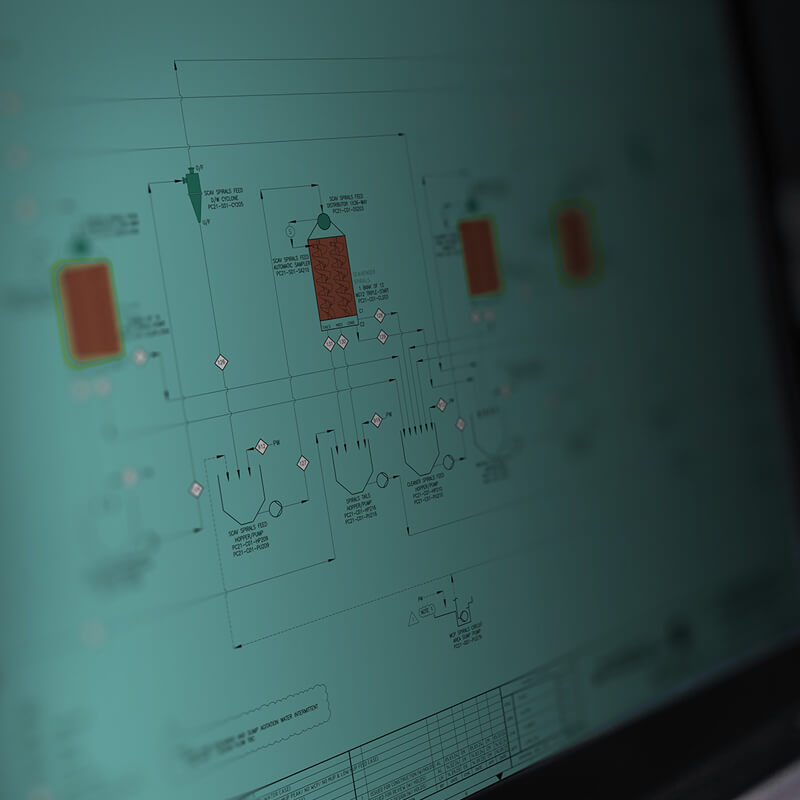

Mineral Technologies is a well-established company with inhouse expertise in Met Services (laboratory and ore analysis). Our testing services will provide you with accurate and reliable information about the composition and properties of your minerals and how you get them best.

Every orebody is different. By analysing your ore samples, we can apply the most effective spirals and other proven MT separation technologies. Benefit from MT experts supporting you with guidance on how to optimise the performance of your plant.

Prevent downtime, reduce maintenance needs, and minimise repairs. In operations – reduce waste, increase yields, and lower operating costs. Testing your ore samples with Mineral Technologies can help you avoid costly mistakes by identifying potential issues with your current spiral separator setup.

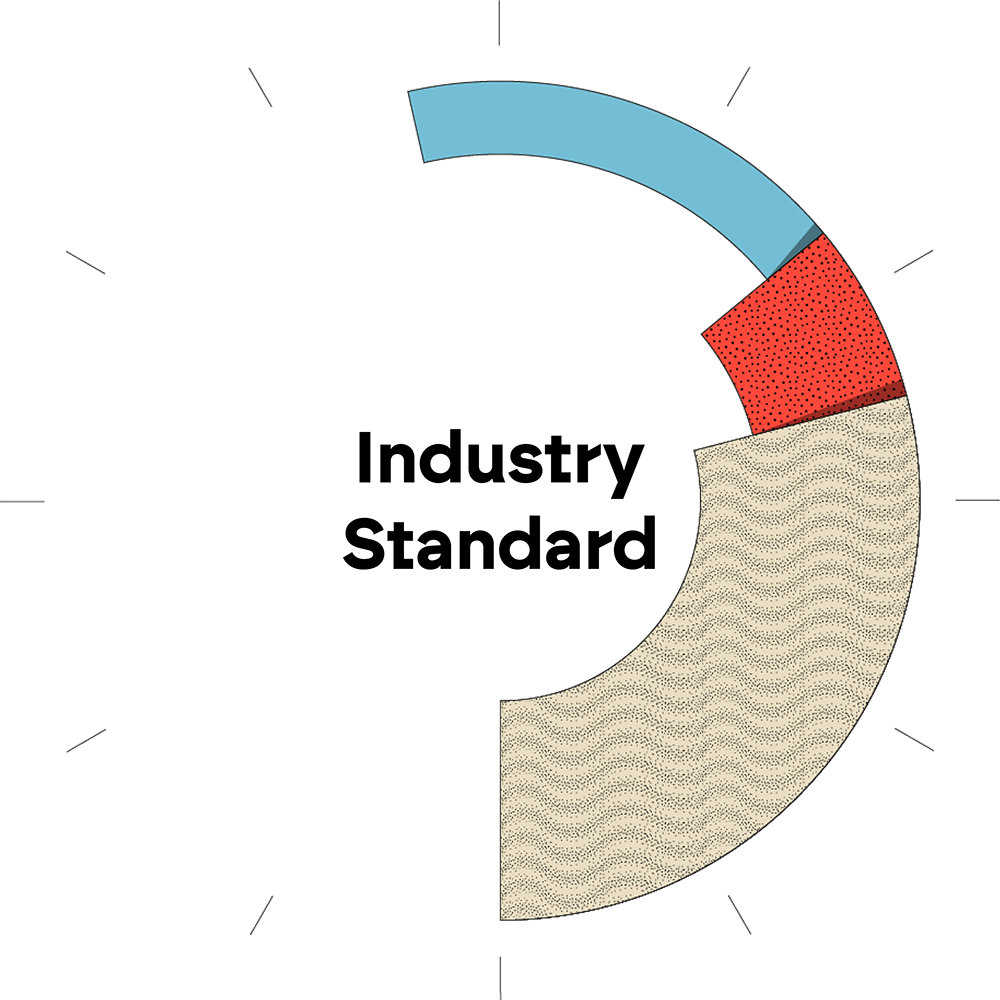

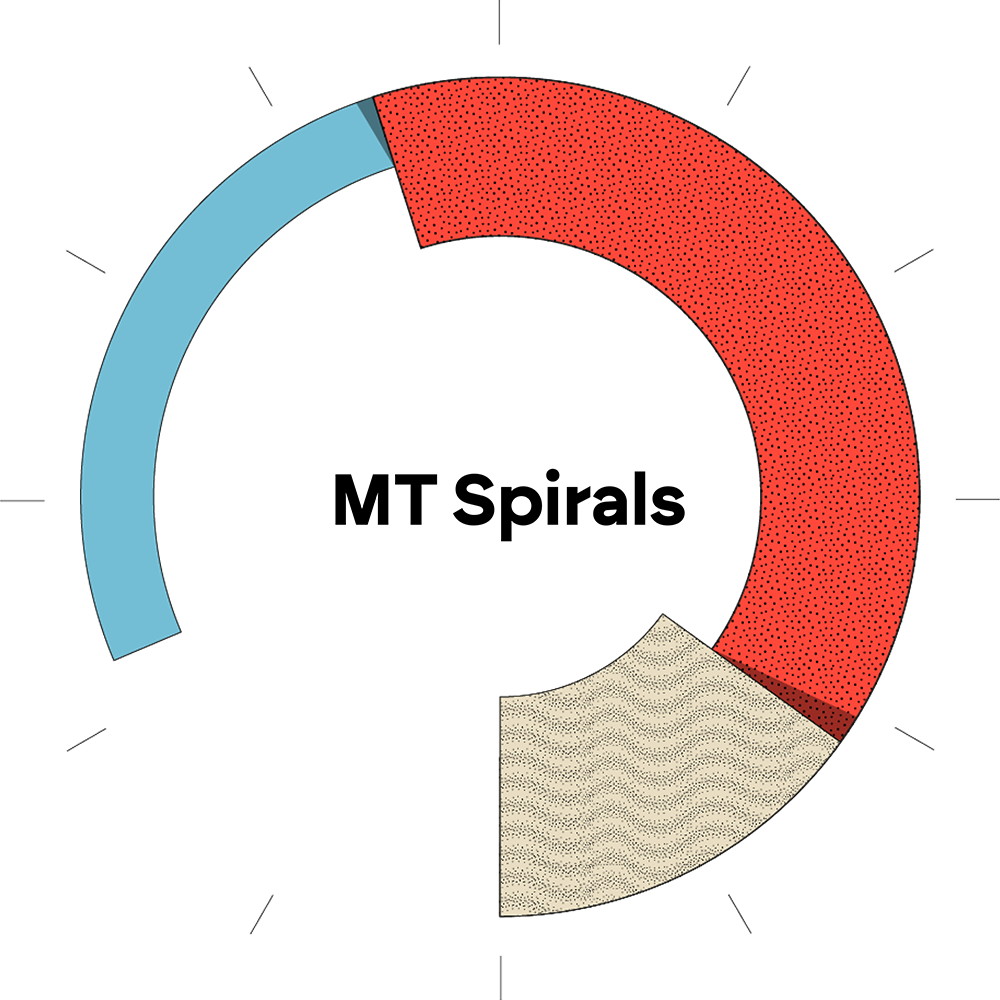

OutperformingIndustry Standards

MT spirals offer superior chrome recovery with a compact design that consumes less space in mines. This advanced technology enhances efficiency and sustainability in mineral processing.

85%

Recovery Rate

15%

Average reduction in waste

<10%

Cr in tails

+1 Million

MT Spirals manufactured

What is Next

What is Next

Spiral intoa sustainablefuture

Our spiral solutions are more than just technological innovations—they are the keys to unlocking the full potential of chrome extraction. By maximising recovery rates, reducing operational costs, and ensuring durability in harsh mining environments, our spirals not only enhance profitability but also pave the way for sustainable mining practices. As the global demand for chrome continues to rise, it is imperative that we embrace solutions that not only meet current needs but also safeguard the future of the industry. We are not just mining chrome; we are shaping the future of chrome extraction for generations to come.

Equipment

Equipment

Proven by results

Our latest range of equipment built by decades of unmatched real world experience.

James Agenbag

Fines Beneficiation Expert

Focus: Fine Minerals

I am a chemical engineer with two passions: physical separation and customers. Let’s solve your processing problems.

The Expert

The Expert

ReachOut!

Ready to explore how our advanced technology can revolutionise your operations? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.