Why it Matters

Why it Matters

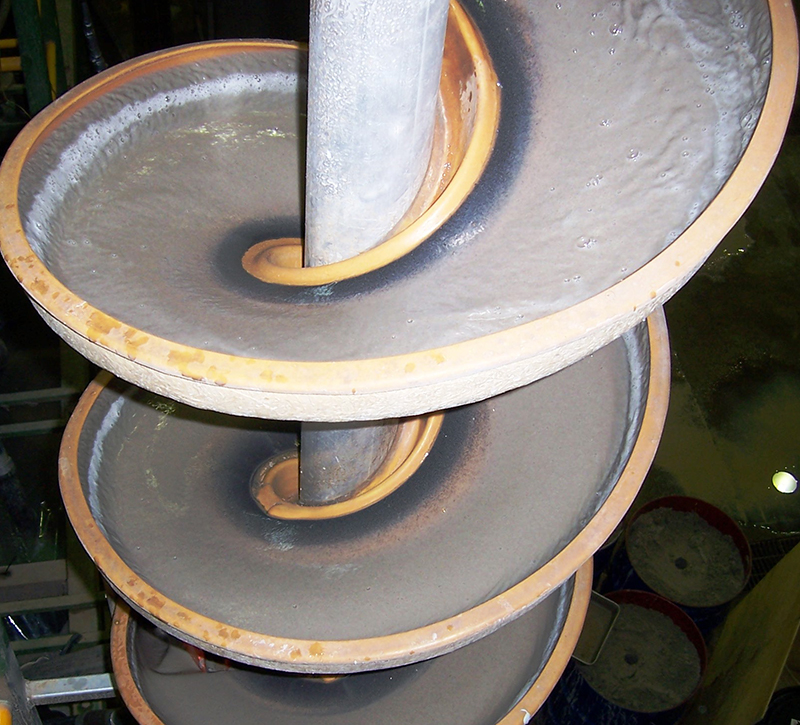

No two ore bodies are the same. Neither are our spirals.

Mineral Technologies understands the complexity of fine mineral separation. That’s why our Spiral Separators are not just products—they’re precision-engineered solutions tailored to your specific ore body. Unlike one-size-fits-all options, we deliver spirals as unique as your challenges, ensuring maximum recovery, throughput, and cost-efficiency.

What makes MT Spirals different?

What makes MT Spirals different?

Unparalleled customization for optimal results

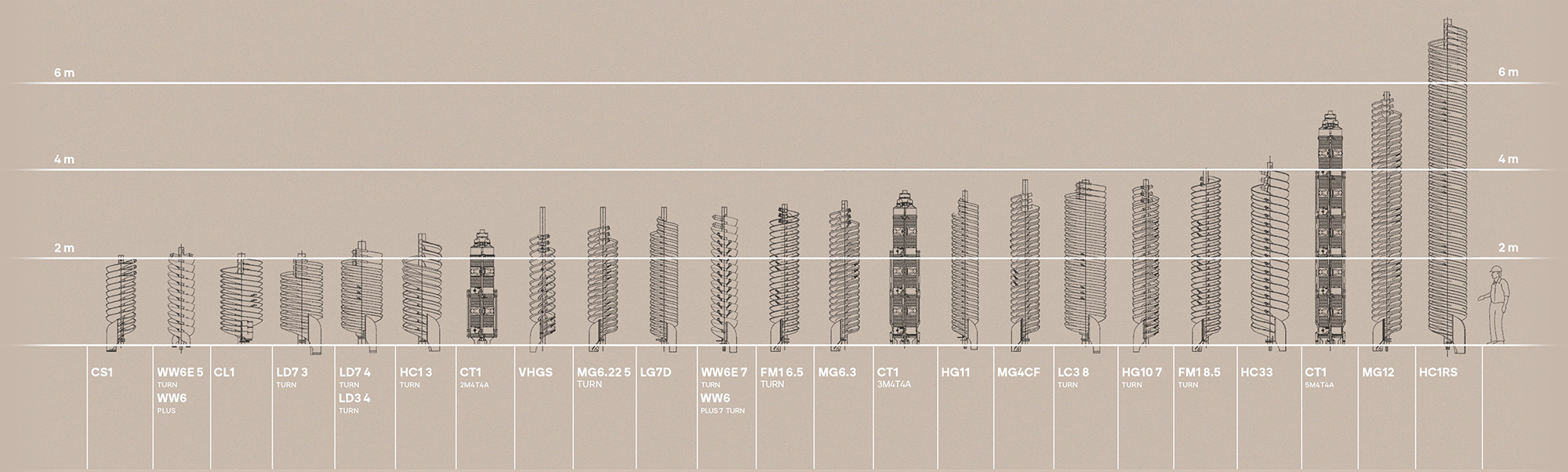

At Mineral Technologies, we offer a range of 20-40 spiral types, each optimized for specific mineral characteristics and separation goals.

Our spirals are designed to maximize recovery rates even with challenging ore variability, reduce tailings waste through sustainable solutions, and enhance efficiency by optimizing the balance between throughput and metallurgical performance.

Key Differentiators

Customized Spiral Designs

Including trough pitch, diameter, and product take-off points.

Proven Success

Case studies like RBM’s tailored spirals outperforming competitors over years of testing.

Industry-Leading Range

Models like MG12, FM1, VHG, and others crafted for diverse needs.

Tailored Solutions

Tailored Solutions

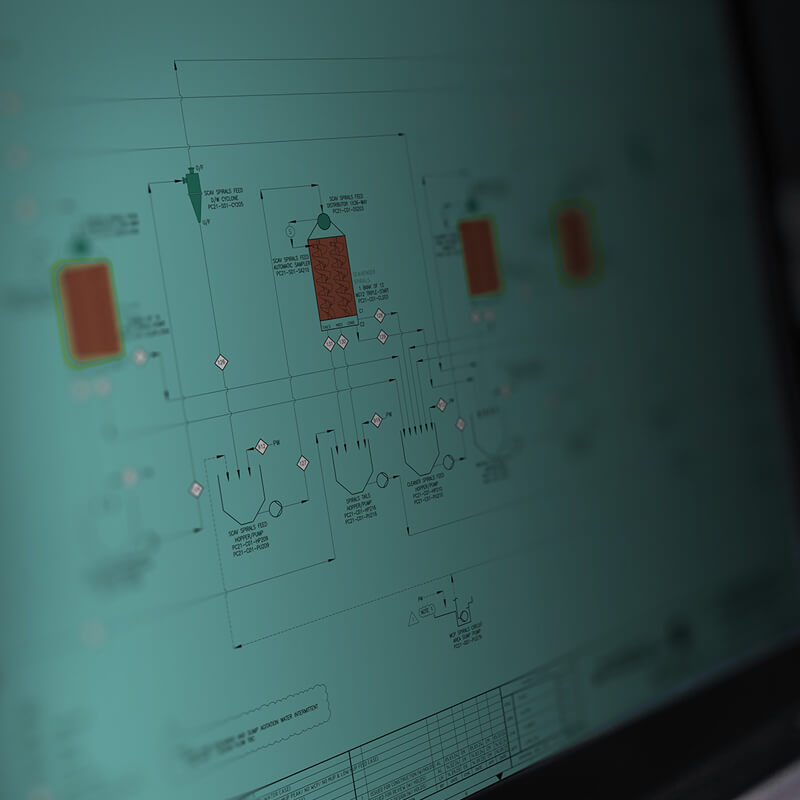

From maximum throughput to optimal performance

Every processing plant aims to achieve maximum throughput, optimal metallurgical performance with a focus on grade and recovery, and cost-effective operations by balancing cost and performance.

Our team collaborates with you to understand these goals, offering custom solutions that align with your specific needs and priorities.

Advanced technology and expertise

Advanced technology and expertise

Innovation that sets us apart

Our spirals are engineered with precision to tackle the complexities of modern ore bodies. Key features include:

- Re-Pulping Techniques: Enhancing grade and recovery.

- Flexible Configurations: Adaptable designs for various processing stages.

- Proprietary Materials: Built for durability and consistent performance under extreme conditions.

Sustainability in mineral processing

Sustainability in mineral processing

Minimizing Waste, Maximizing Resources

Mineral Technologies is committed to sustainable mineral recovery. By reducing waste in tailings and optimizing resource recovery, our spirals contribute to a greener future while enhancing operational efficiency.

Shane Anderson

Product Manager – Spirals

Focus: Mineral Separation

Witnessing a 3D concept model spring into existence, whether it’s a tiny plant or a single component, and realising I contributed to its design and development is immensely rewarding.

The Expert

The Expert

ReachOut!

Ready to explore how our advanced spirals can revolutionise your operations? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.

Get detailed Insights

Get detailed Insights

Success Stories

Explore how our metallurgical testing expertise has driven success for global projects. From mineral sands in Australia to complex tailings reprocessing globally, our solutions deliver measurable results.