Why it matters

Why it matters

Enhanced Solutions for Silica, Coal & Tin

We deliver cutting-edge mineral processing solutions across a wide range of industrial minerals and metals, including silica sand, coal, tin, and tungsten ores, as well as tailings re-processing. Our expertise enhances separation efficiencies while promoting sustainable practices.

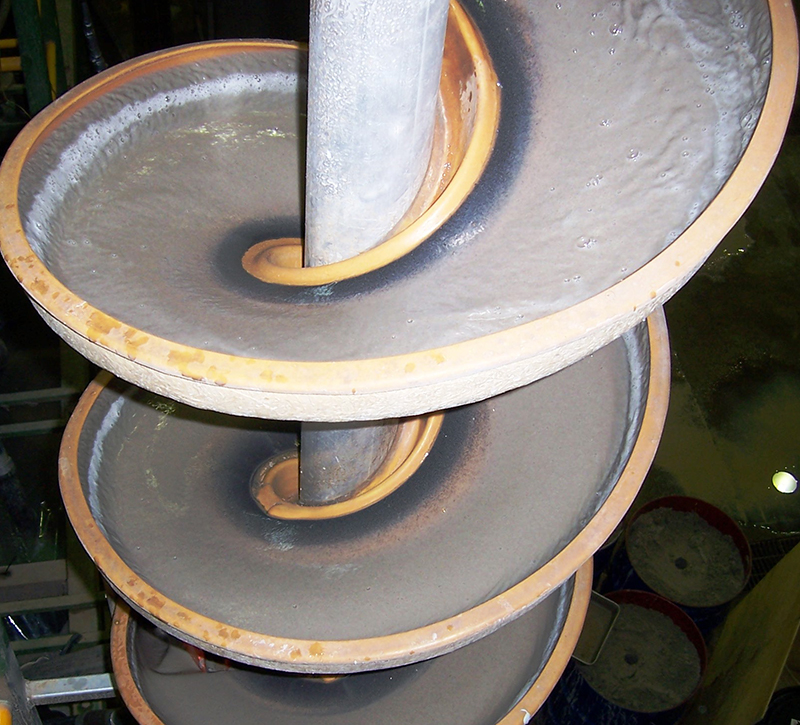

For silica sand, our metallurgical characterization, testing, and flowsheet development services ensure high recoveries, consistent product quality, and cost-effective processing. In coal processing, our globally recognized spiral designs maximize grades and recoveries, treating millions of tonnes of fine coal worldwide.

Projects

Projects

Proven realworld success

Why it matters

Why it matters

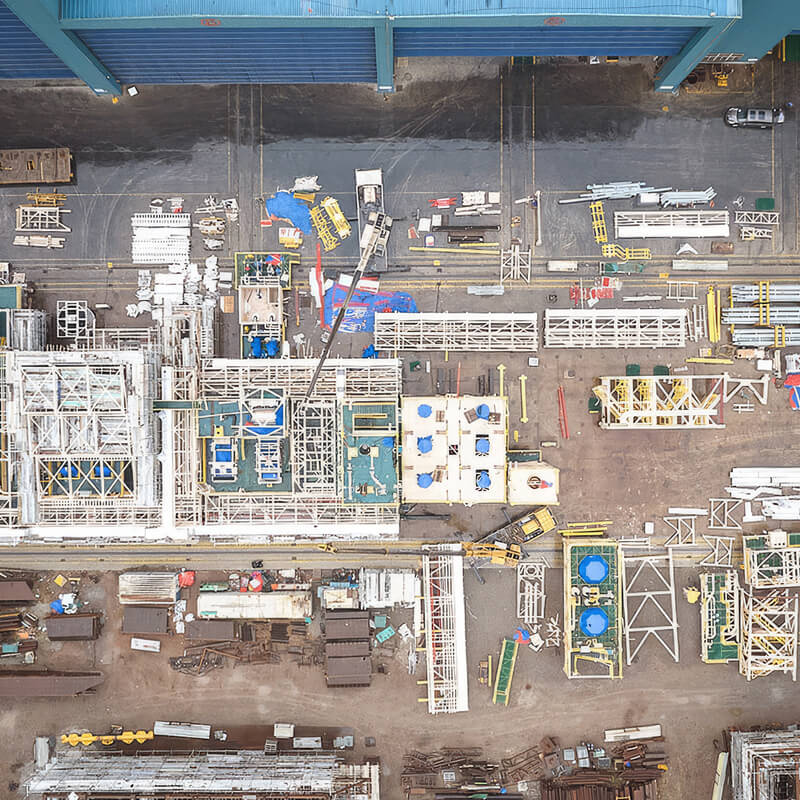

GlobalExpertise

From our beginnings in the 1940s separating fine minerals along Australia’s east coast, we have expanded to become the global leader in mineral sands processing. From Senegal’s largest mineral sands plant, Grande Côte, to Chemours on North America’s east coast, and numerous projects in Africa, India, Europe, and Australasia, our teams provide unmatched expertise in mineral sands processing throughout the project lifecycle.

Backed by 80 years of experience, our proven technologies not only improve recoveries and product quality but also drive significant water and energy savings for more sustainable mining operations.

Advantages

Advantages

You have the upper hand

- Enhanced Recovery and Quality: Advanced processing solutions for superior recovery and grade of coal, silica sand, and tin.

- Robust Equipment Design: Durable spirals and separation technology tailored to withstand challenging conditions, reducing maintenance and downtime.

- Customised Processing: Solutions adapted to specific mineral characteristics and operational needs, ensuring optimal performance.

- Sustainable Practices: Focus on reducing water use and minimising waste, promoting environmentally responsible operations.

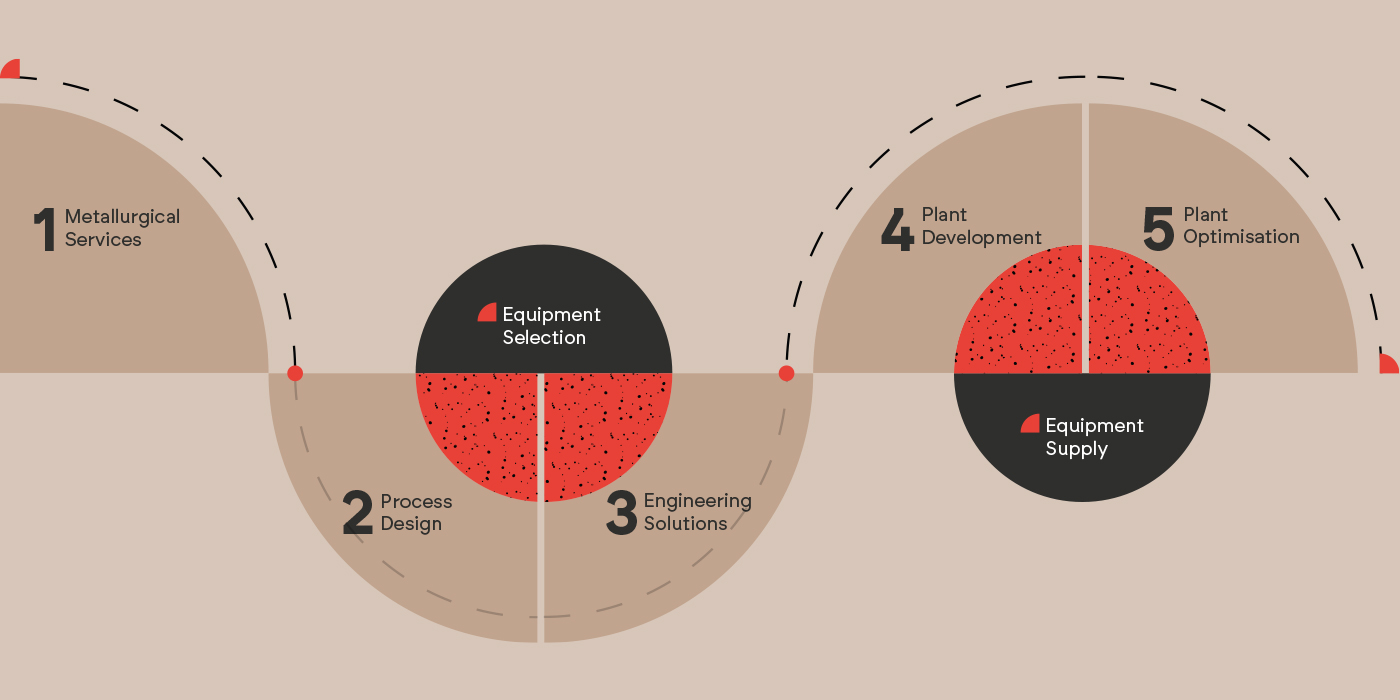

- Comprehensive Support: Full lifecycle support from mineral testing through to plant commissioning and ongoing operational refinement.

The Challenge

The Challenge

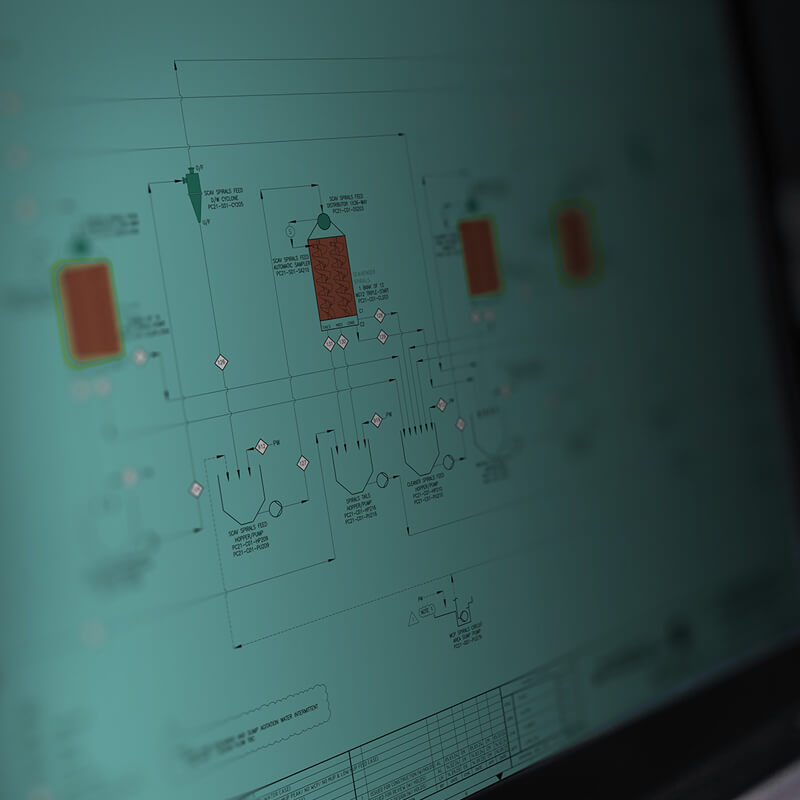

Earth First approachto industrial minerals

From initial test-work to final plant design, we provide concept, pre-feasibility, and feasibility studies along with cost-effective flowsheets for extracting industrial minerals. Our process engineers excel in maximising the extraction of fine minerals, offering innovative solutions for unique ore bodies. We design plants capable of processing 5 to 7,000 tonnes per hour, incorporating gravity, electrostatic, and magnetic equipment. Our FlexSeries plants are modular and relocatable, offering customisable options for any mineral resource, ensuring high performance without compromising on cost or environmental standards.

Solutions

Solutions

Latest industrial mineralsequipment range

Our latest range of equipment built by decades of unmatched real world experience.

Brenda Van Rhyn

Regional Manager – Australia

Focus: Fine Minerals Recovery

I am a results-driven chemical engineer, passionate about delivering innovative equipment solutions that maximize revenue while minimizing costs.

The Expert

The Expert

ReachOut!

Ready to explore how our advanced solutions can revolutionise your industrial minerals operations? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.