Why it matters

Why it matters

Enduringprecision

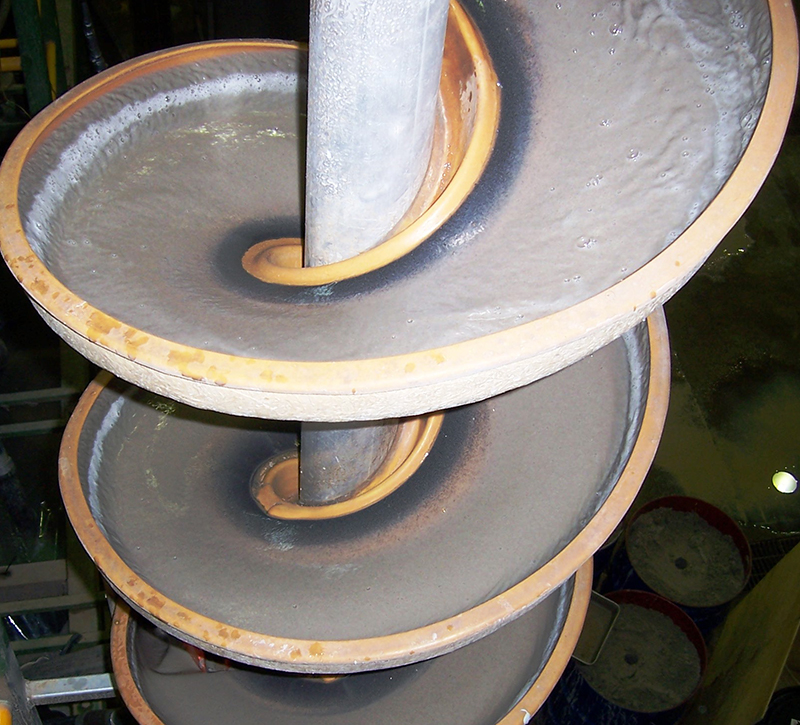

Separating fine, free-flowing materials with varying conductivity—such as ilmenite, rutile, and recyclables—remains a significant challenge in mineral processing.

Where traditional methods fall short, the MT Carrara series excel with advanced roll designs and precision electrodes, ensuring high recovery, minimal waste, and low-maintenance performance.

Built for durability, some of these machines are still performing consistently after more than 30 years in operation. With standard and customisable solutions, Carrara separators maximise plant availability and streamline operations, ensuring seamless integration into production systems.

The Solution

The Solution

Tirelessperformance

The HTR400 is an advanced separator featuring a 400mm diameter roll, designed to boost throughput and separation efficiency. Ideal for processing fine mineral sands and titaniferous ores, it provides high-purity separation with minimal waste, meeting the needs of clients in mineral sands, iron ore, and beyond.

With a 270mm roll, the HTR270 is suitable for high-capacity, precision separation in industrial-scale applications. This separator handles a wide particle size range and is effective for separating materials with close conductivity differences, making it ideal for separating minerals like ilmenite, rutile, and zircon.

The Carrara ESP excels in separating free-flowing, dry minerals based on conductivity. This equipment is particularly useful for separating coarse and fine materials such as mineral sands, chromite, and cassiterite. Its multi-stage design allows for optimal recovery and adaptability across various mineral processing tasks.

Technology

Technology

Bringingdynamic tostatic

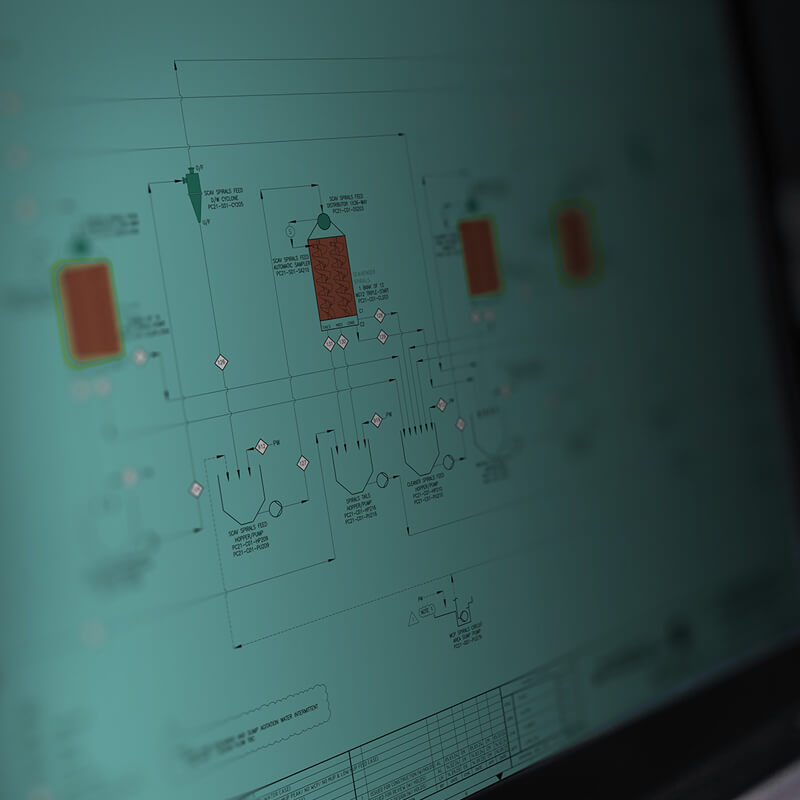

The MT Carrara series offers flexible, efficient processing of materials, from fine concentrates to industrial minerals, with enhanced performance.

Plate and Screen Plate Electrostatic Separators

- Five Stages of Separation: Internally configured for non-conductor re-treatment.

- Laboratory Scale Separators: Available for testing and development purposes.

High Tension Roll Separator (HTR)

- Multiple Roll Stages: Supplied with either two or three roll stages for non-conductor cleaning, conductor cleaning, or middlings retreatment.

- Model Options: HTR rolls are available in 270mm and 400mm diameter models.

- Laboratory Units: Available for detailed analysis and testing.

Benefits

Benefits

The obvious choice

Increased throughput

Significantly boost productivity by over 25% with innovative designs, processing more material in less time and enhancing profitability.

Enhanced separation

Our superior separation efficiently processes a wide range of particle sizes, leading to higher purity outputs and reducing the need for additional processing steps.

Improved flexibility

Easily adapt to various operational needs with a flexible configuration and modular design that allows for seamless integration and easy scale-up within existing infrastructure.

Trusted Reliability

Our separators are mechanically reliable, performing efficiently even under the most intense heat and in extremely dusty environments. Some of our machines have been operating for 30+ years and still going!

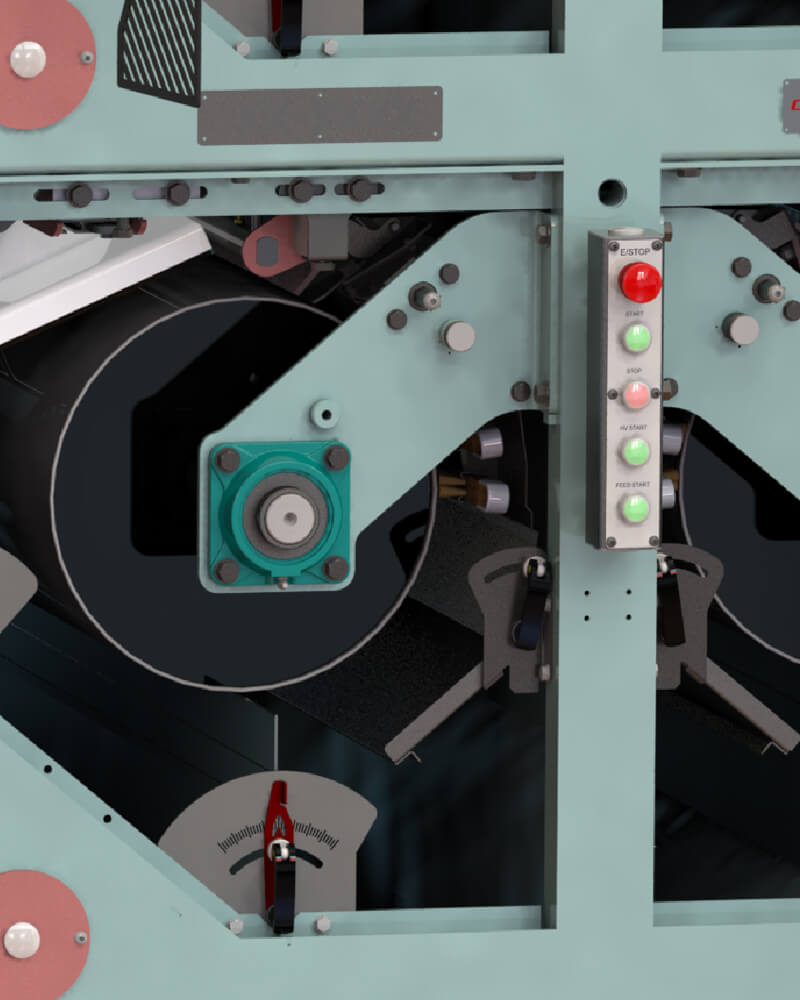

Enhanced Operator Safety

Dust proof enclosures ensure a safer workplace, these guards still allow operators to do their inspections. Protecting them from potential hazards and complying with safety regulations.

Customised Solutions

Receive tailored solutions and engineering support to meet your specific needs, optimising processes to achieve the best possible outcomes for your operation.

Features

Features

Finely tunedseparation

Our independently adjustable electrode systems allows for precise control over separation processes.

For enhanced operator convenience and safety during online inspections, each separation module is equipped with its own inspection door—streamlining access while reducing heat loss and dust exposure.

Featuring a fluted feed roller powered by a geared motor and variable frequency drive, our system offers precise feed control and seamless automated operation. With proven calibration techniques, it ensures accurate feeding across multiple machines.

Our adjustable splitter design effortlessly accommodates middlings, non-conductors, or conductor retreats without the need for chute changes— fine tuning and enhancing separation.

MT Carraraby the numbers:

50%

The amount of throughput increased since 19xx

400mm

Up to 400 mm dia options.

40-800

Microns particle size range for effective separation of dry, free-flowing materials.

40+ years

There are separators still in operation and performing consistently for the last 40 years.

TechnicalSpecifications

HTR400

HTR270

ESP

Maximum throughput will vary with application and testwork is required for confirmation.

Nicolas Boonzaier

Product Manager Lyons Unit, Magnets

Focus: Advanced fines processing equipment

The Expert

The Expert

ReachOut!

Ready to explore how our technology can revolutionise your operations? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.

Get detailed Insights

Get detailed Insights

Success Stories

Explore how our expertise has driven success for global projects. From mineral sands in Australia to complex tailings reprocessing globally, our solutions deliver measurable results.