Why it matters

Why it matters

DrivingProfitability,Sustainably

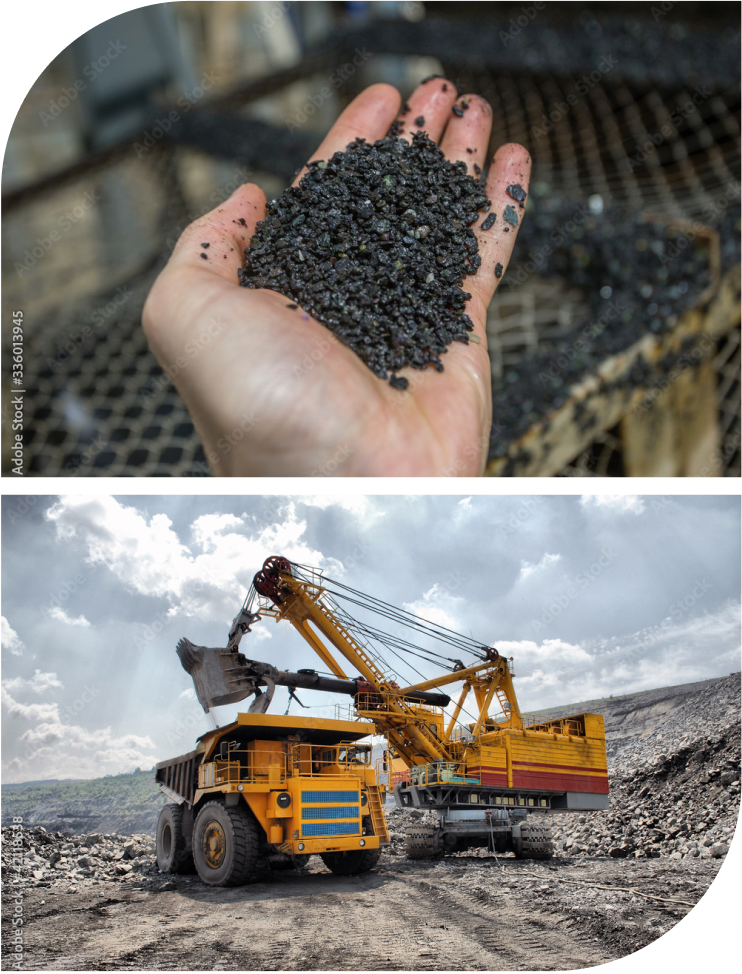

In mineral sands mining, transporting raw feed material is a constant challenge that impacts operational costs and environmental footprint. Addressing this issue is crucial for enhancing profitability while promoting sustainable practices.

The Challenge

The Challenge

ConventionalConstraintsOvercome

Traditional mining methods like truck-and-shovel operations are carbon-intensive, labor-intensive, and capital-intensive. They also pose risks of environmental degradation and community disruption due to expansive mining footprints and transportation requirements.

Solution

Solution

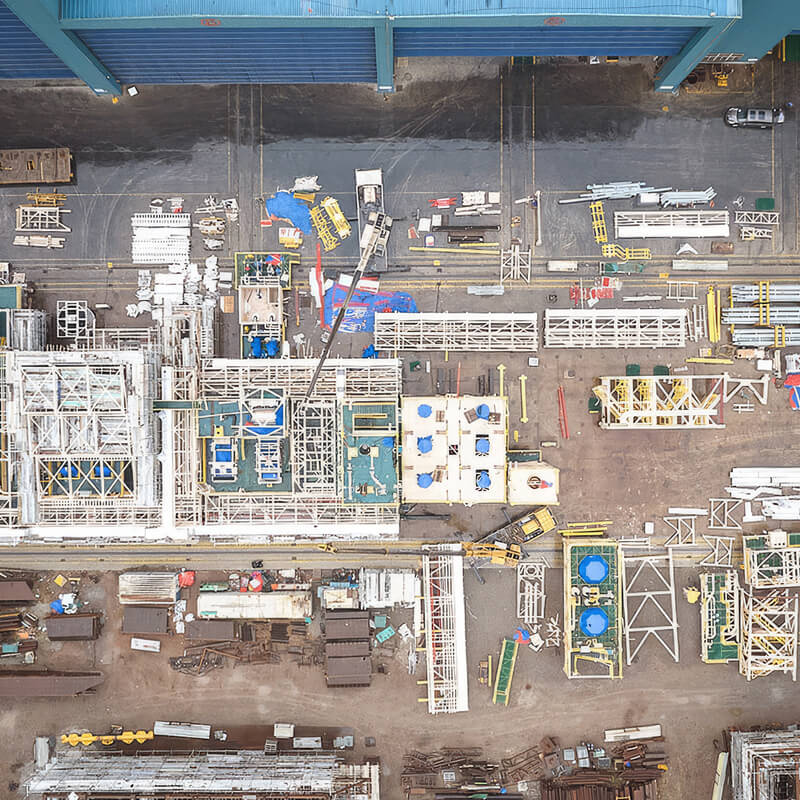

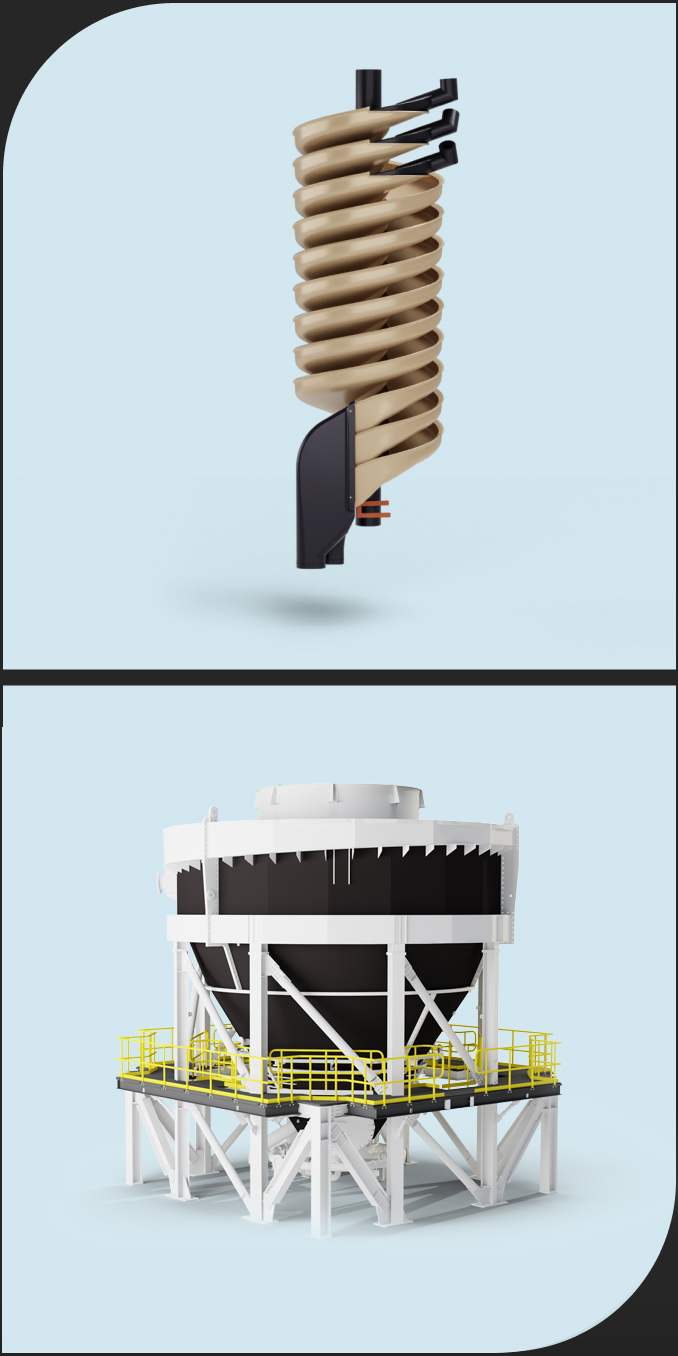

Mobile Mining Redefined

The Mobile Mining Unit (MMU) revolutionizes raw material transportation. This cutting-edge technology efficiently processes minerals on-site, eliminating the need for constant hauling between extraction and processing points.

- MMU Dry Feed – 750 TPH

- MMU Slurry Discharge – 42% solids

The Solution

The Solution

Choose yourweapon

Unlock new revenue streams by extracting valuable minerals from tailings previously considered waste. This process generates additional income and reduces the need for new mining operations.

Recover and recycle up to 90% of process water, significantly reducing fresh water consumption. This is crucial in arid regions and helps preserve local water resources.

Process tailings on-site to eliminate the need for expansive tailings dams, reducing land use and mitigating the risk of dam failures.

Customise our approach with tailored process designs to maximise resource recovery efficiently, ensuring effective and economically viable solutions for each mining operation.

With decades of experience in tailings processing, our expertise ensures robust and effective solutions. Our successful projects worldwide provide confidence in our ability to deliver reliable outcomes.

Reduce energy usage, water consumption, and waste volumes, enabling more sustainable mining practices. This helps in reducing CO2 emissions and aligns with global sustainability goals.

50% Reduction

The MMU can reduce operating costs by up to 50% compared to traditional truck-and-shovel dry mining operations.

460 Million tonnes

The mineral sands industry alone extracts around 460 million tonnes of materials per year.

70% Less C02

The MMU technology can achieve up to 70% reduction in CO2 emissions compared to conventional dry mining methods.

$1.2 Billion

Extraction costs estimated at $1.2 billion annually.

What is Next

What is Next

Sustainable Mining,Resilient Future

Prioritize environmental stewardship while driving profitability. Our innovative MMU harmonizes resource extraction with sustainable practices, minimizing land use, water consumption, and carbon emissions, securing a resilient future for mining operations and local communities.

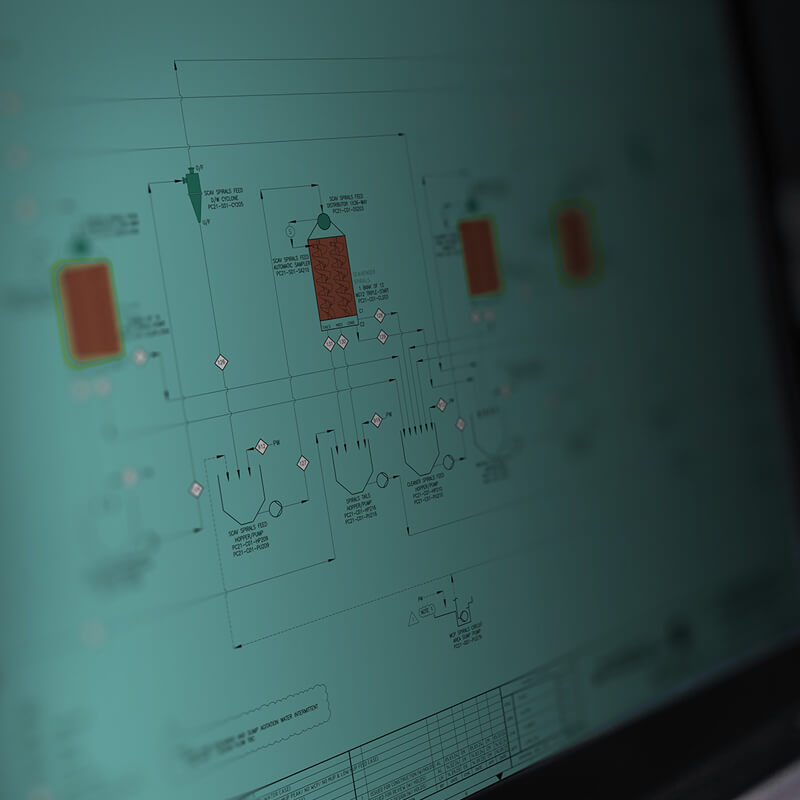

Equipment

Equipment

Proven by results

Our latest range of equipment built by decades of unmatched real world experience.

Dustin Pepper

Head of Products | Driving Innovation in Mining & Mineral Processing

The Expert

The Expert

ReachOut!

Ready to explore how our advanced Mobile Mining Unit can revolutionise your operations? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.