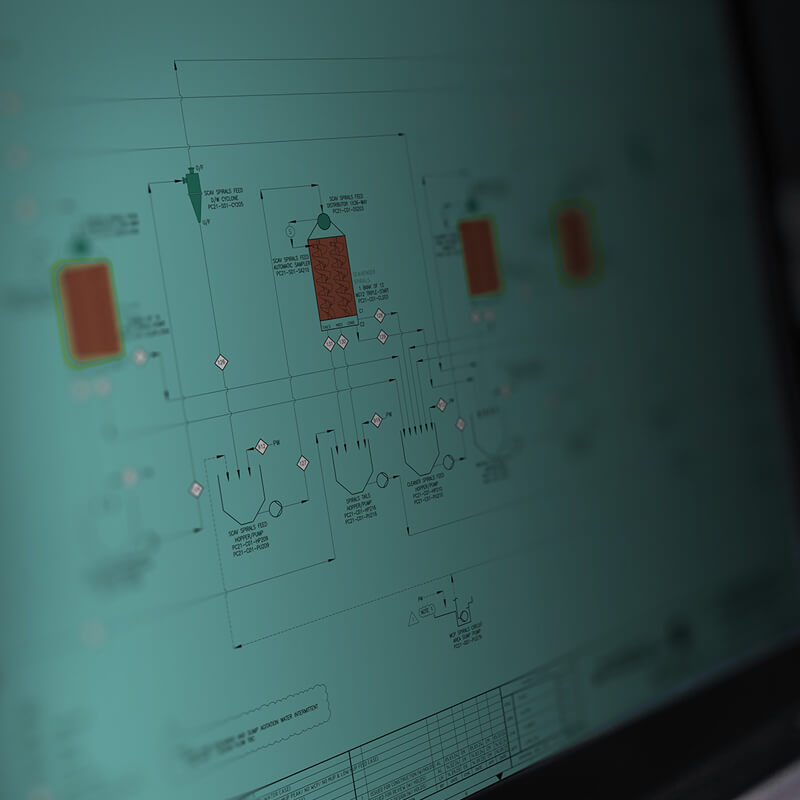

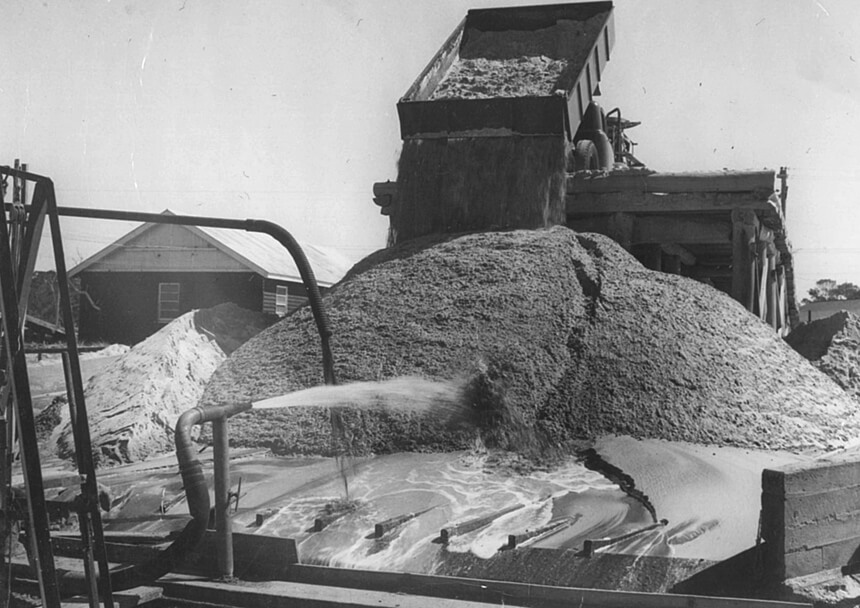

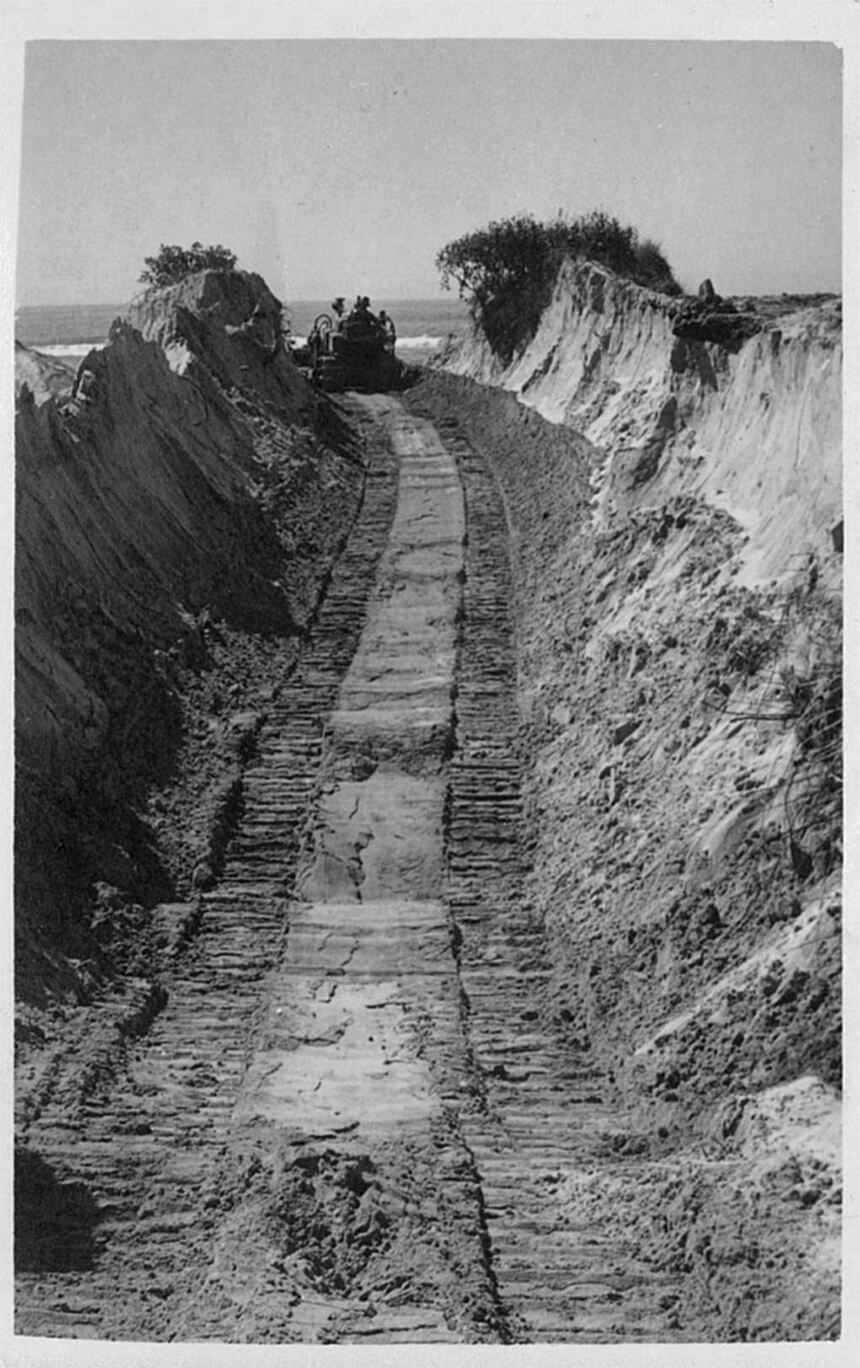

– Delivery of raw material for processing showing monitor in operation, Southport, 1949

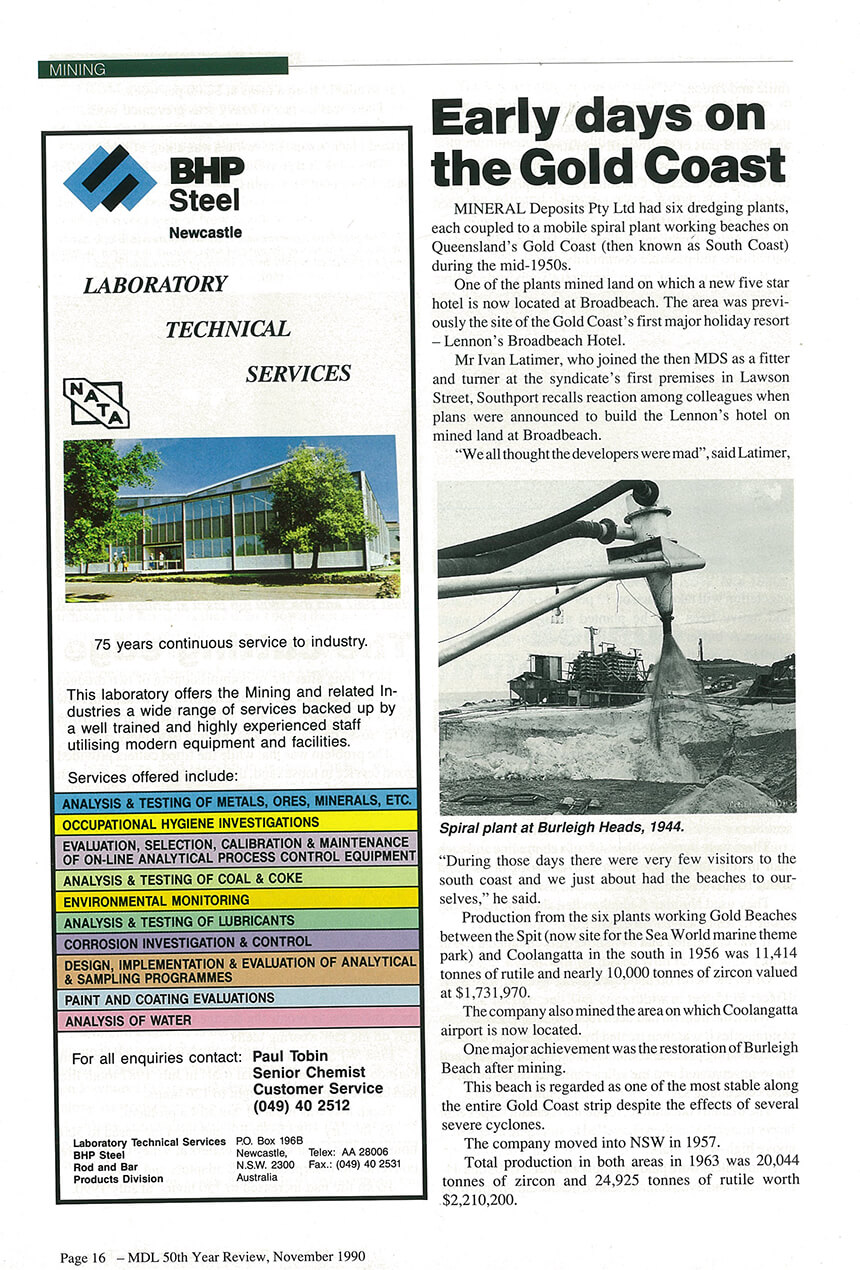

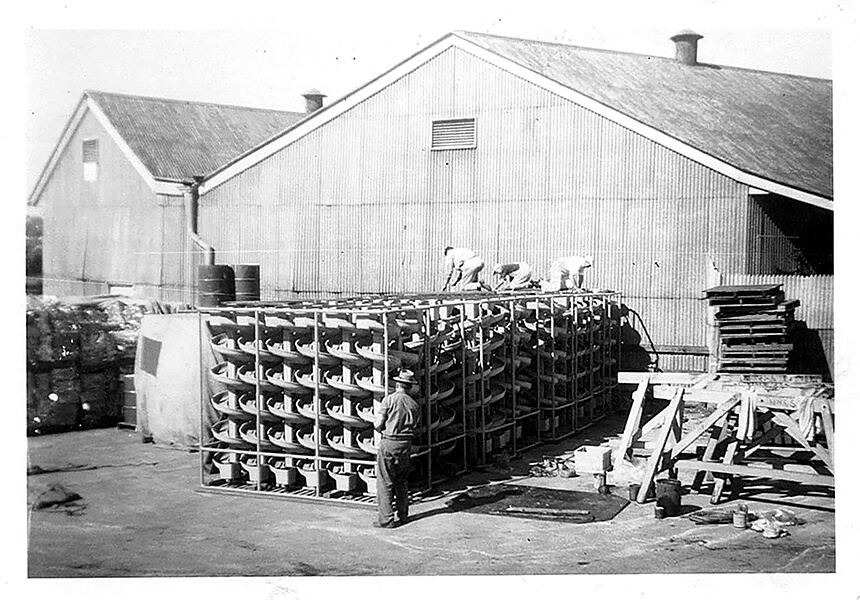

– Spiral Plant, Burleigh Heads, 1944

1940s

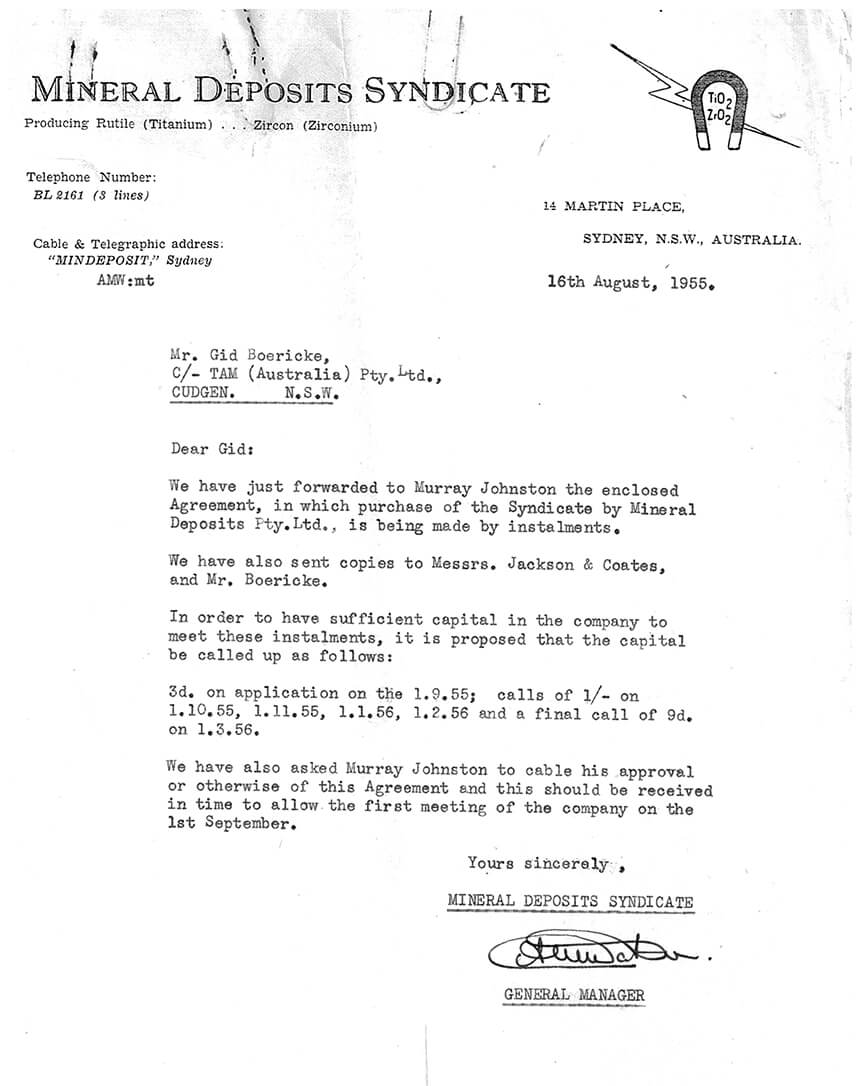

In the 1940s Bert Watson and a handful of other investors established Mineral Deposits Syndicate (MDS).

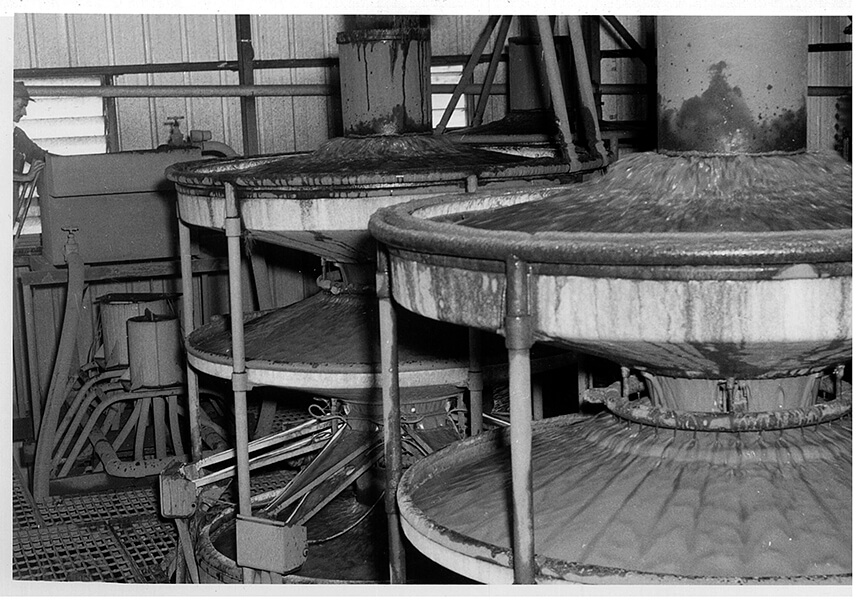

With operations based on the Gold Coast, mineral was shovelled off the beach into trucks before being dried and exported. Lower grade material was processed over crude spirals made from tyres and concrete on the banks of the Nerang River at Brighton Parade, Southport to extract the valuable heavy minerals. Joining MDS in 1946, Ernst Reichert developed electrostatic plate separators for use in the Southport plant.

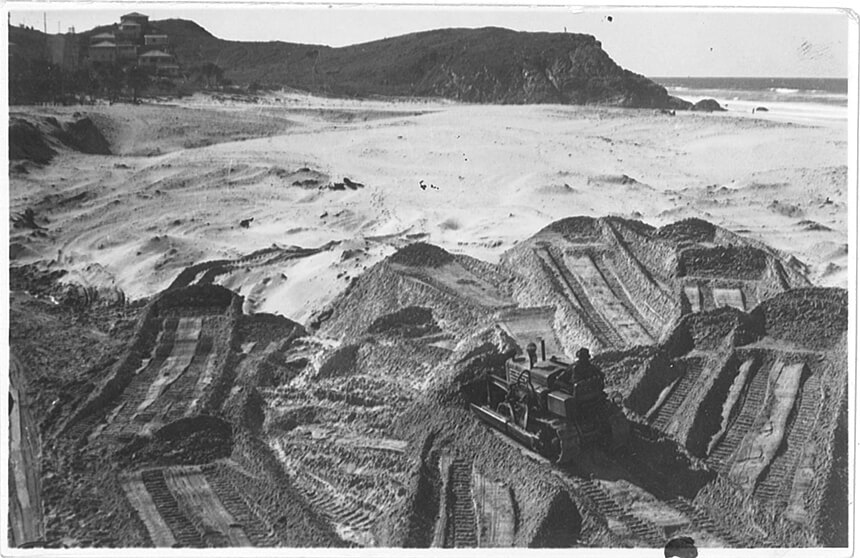

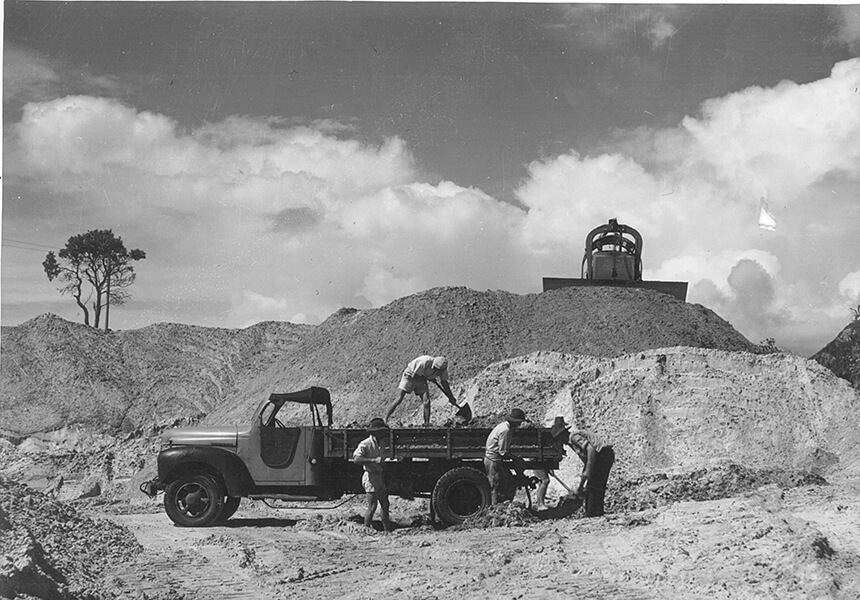

Early mining activities in the 1940s.

– General view of mining operations at Burleigh, showing pit above, with rehabilitation progress by bulldozer, 1944/45

– Dewatering heavy mineral concentrates after tabling, Southport, 1949

– Delivery of raw material for processing showing monitor in operation, Southport, 1949

1950s

1952

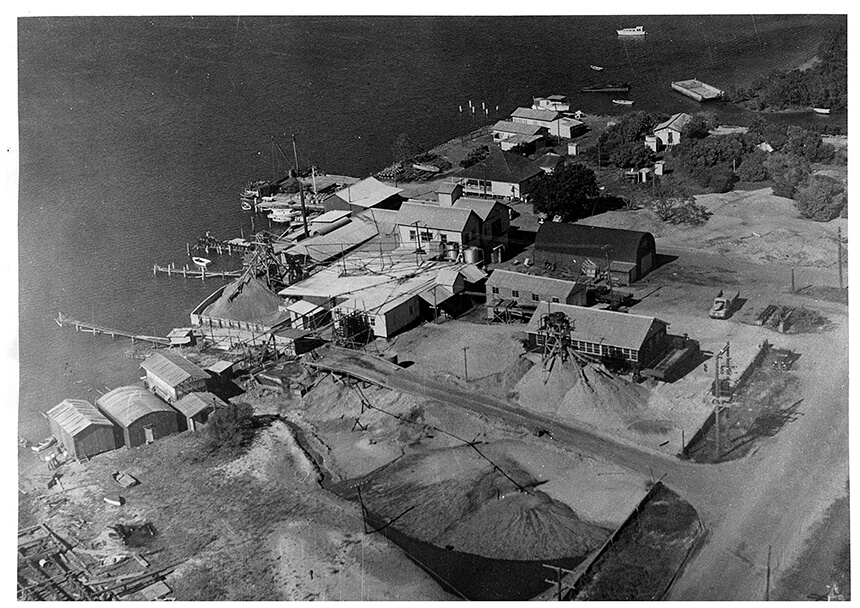

Mineral Deposits Pty Ltd, Southport

1955

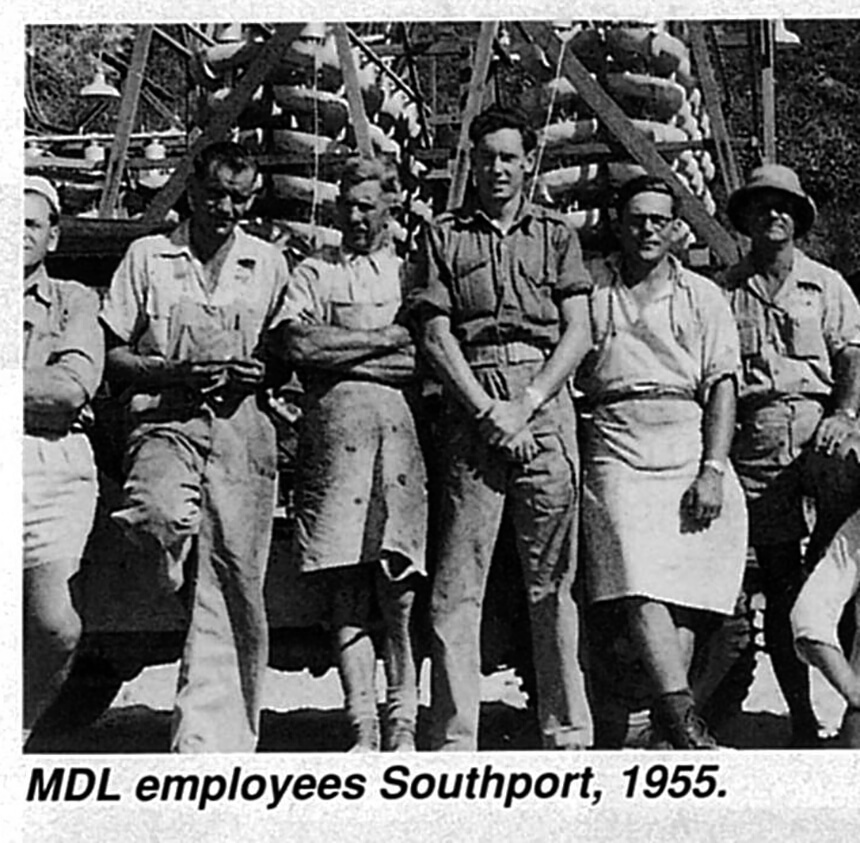

The National Lead Company acquired a controlling interest in forming Mineral Deposits Pty Ltd (MDL) in 1955.

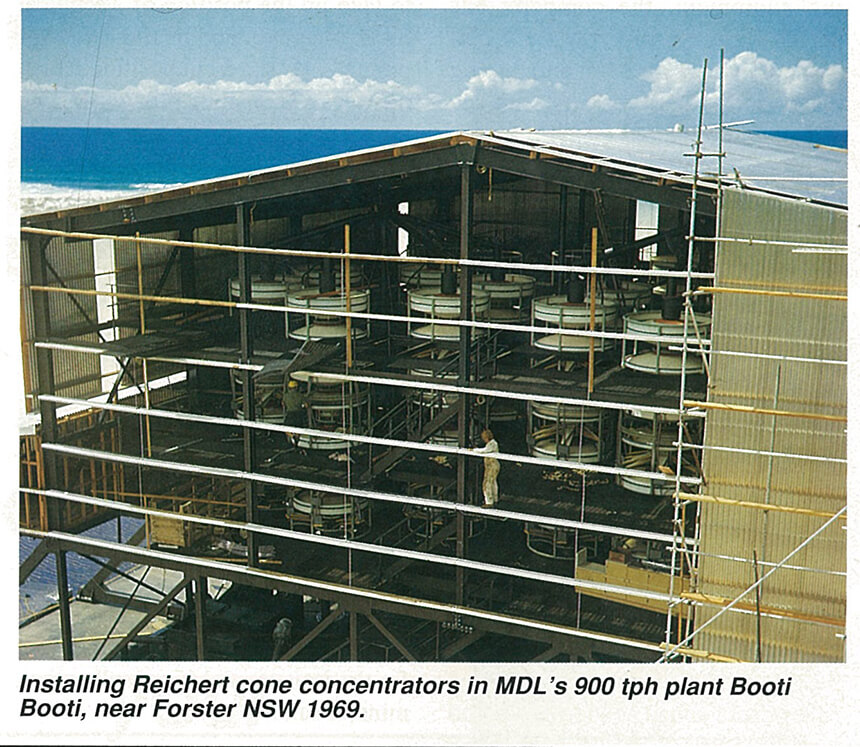

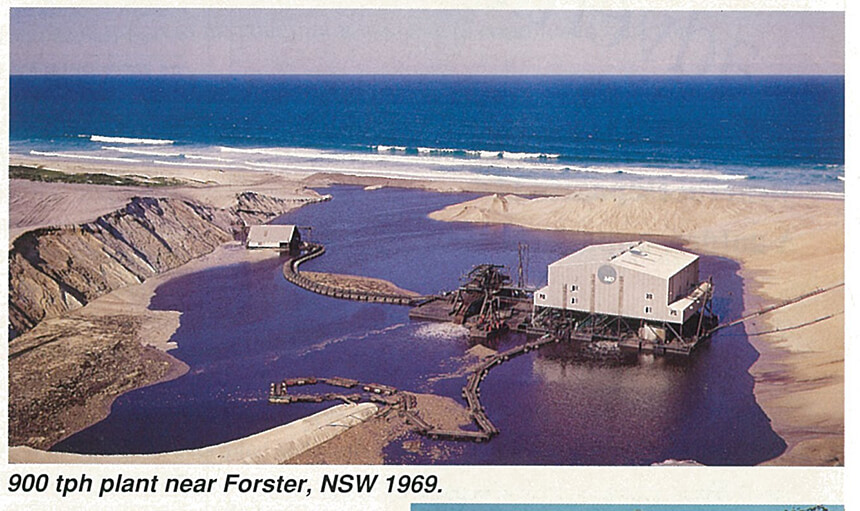

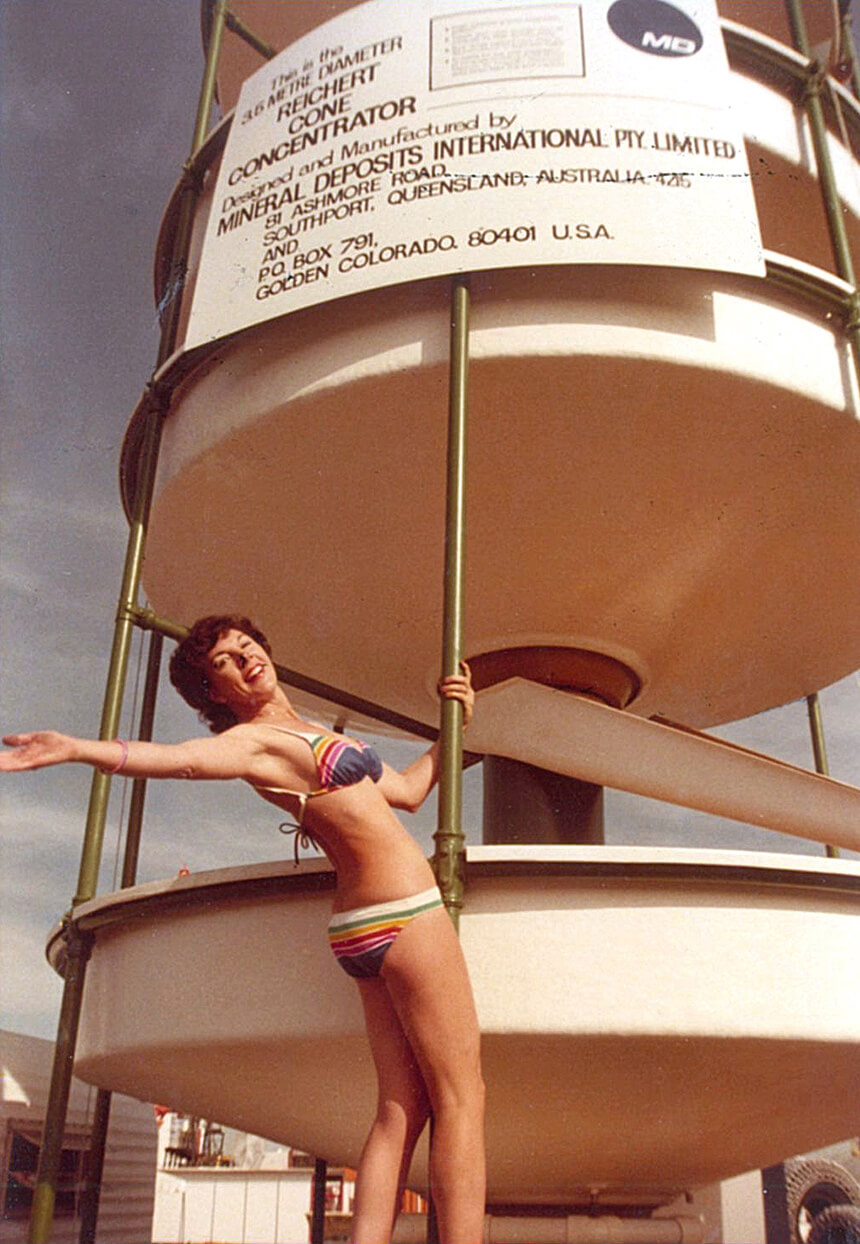

Six dredging and mobile spiral separation plants were established on Gold Coast beaches from the Spit to Coolangatta. During this decade Ernst Reichert developed the first Cone Concentrators to provide improved separation performance over the rudimentary spiral technology of the time. In 1957 MDL developed its Crescent Head operation in NSW utilising newly developed MDL equipment.

1950s

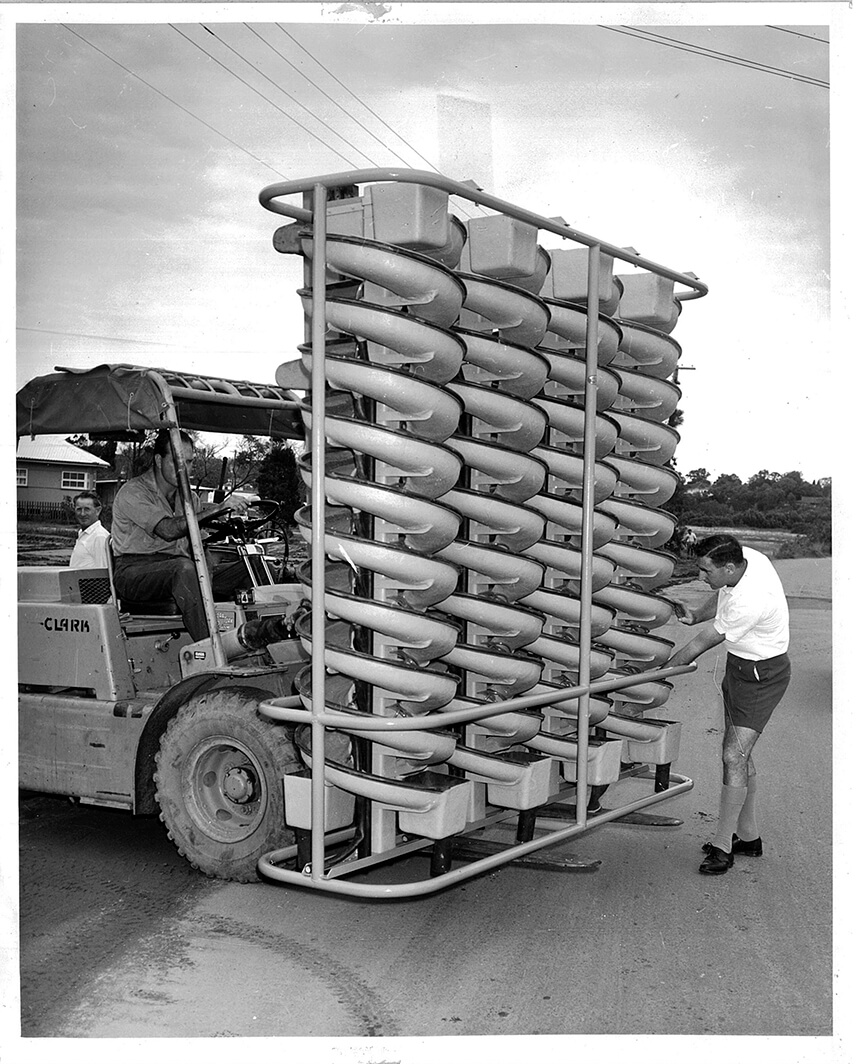

Spiral Production and loading for Shipment, Southport, 1950s

1960s

1960s

MDL developed and manufactured the first fibreglass spirals for its own use and started to manufacture for export.

Listed as a public company in 1967, MDL ceased mining on the Gold Coast in that same year and in 1968 commissioned a new mining operation in Hawks Nest, NSW. The Reichert Mining Equipment Division was established to manage MDL’s equipment manufacturing and plant design activities. Technical marketing and sales of MDL equipment and services started in the late 1960s.

– MDL employee Ivan Latimer adjusts MkI High Tension Separator, 1963

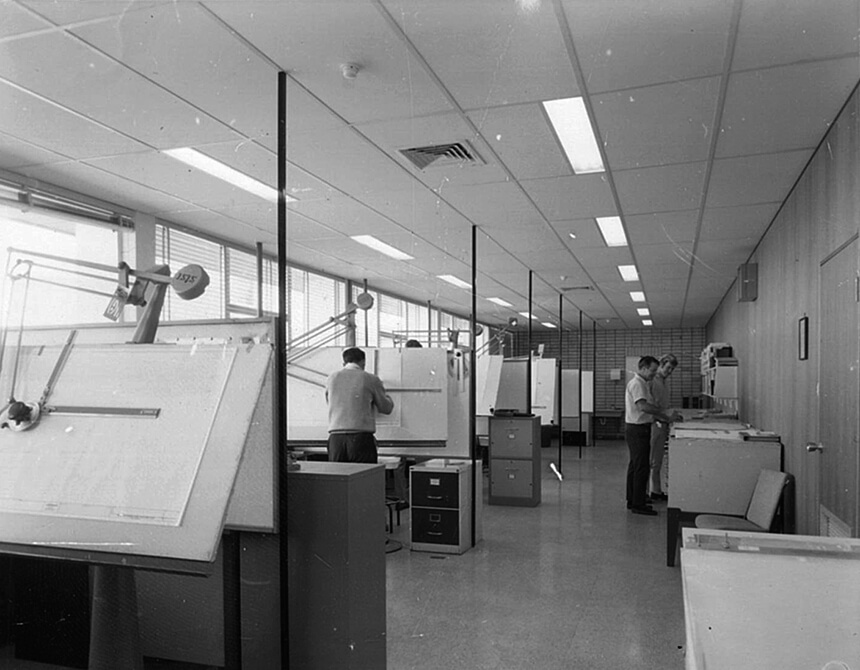

– Drawing Office, Southport, 1968

1970s

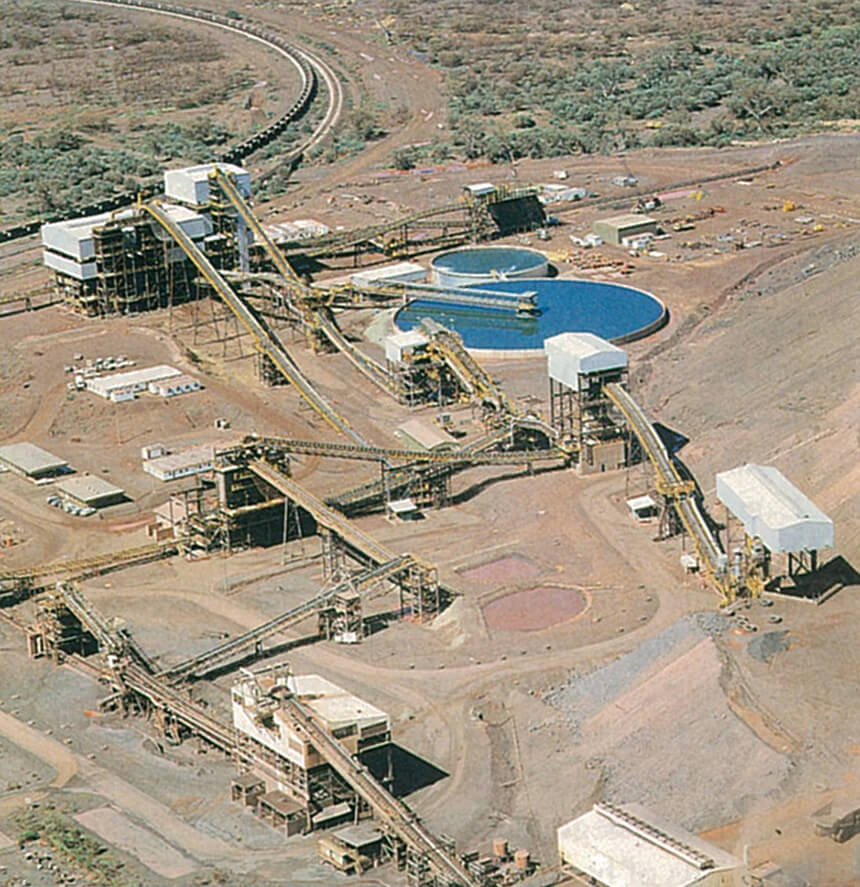

MDL had 10 wet separation plants and 3 mineral separation plants in operation, and for a time was the second largest producer of rutile and zircon in the world.

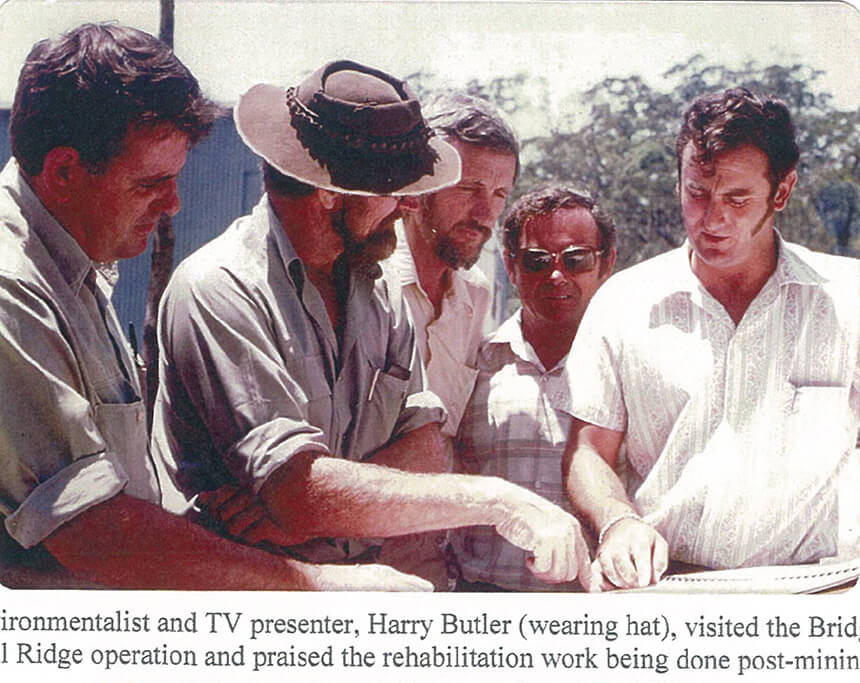

MDL prepared the first ever environmental impact statement in Australia for a mining operation which included the ultimate rehabilitation of its proposed Bridge Hill Ridge operation in New South Wales.

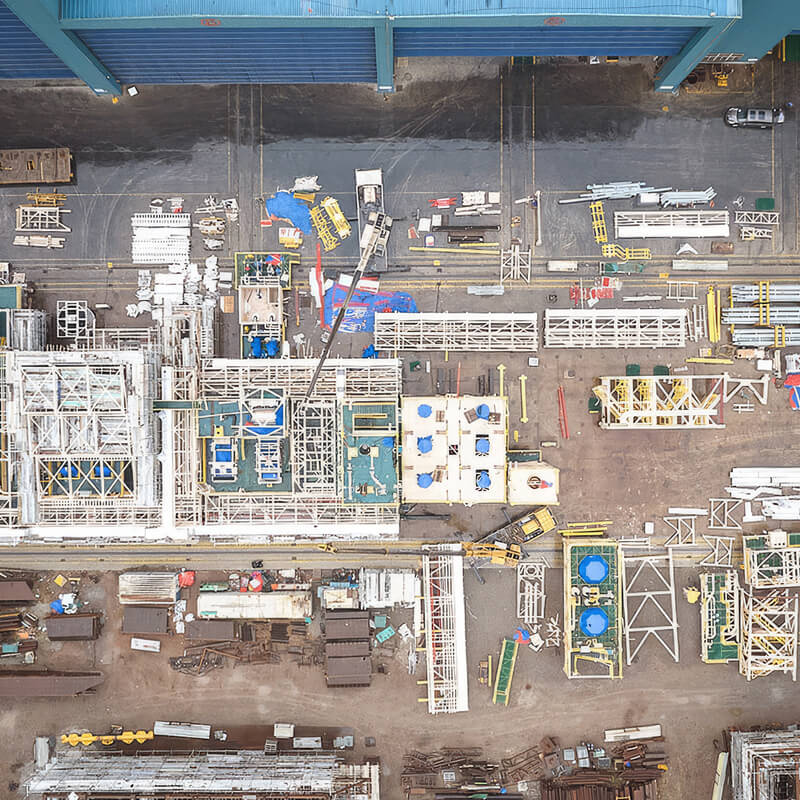

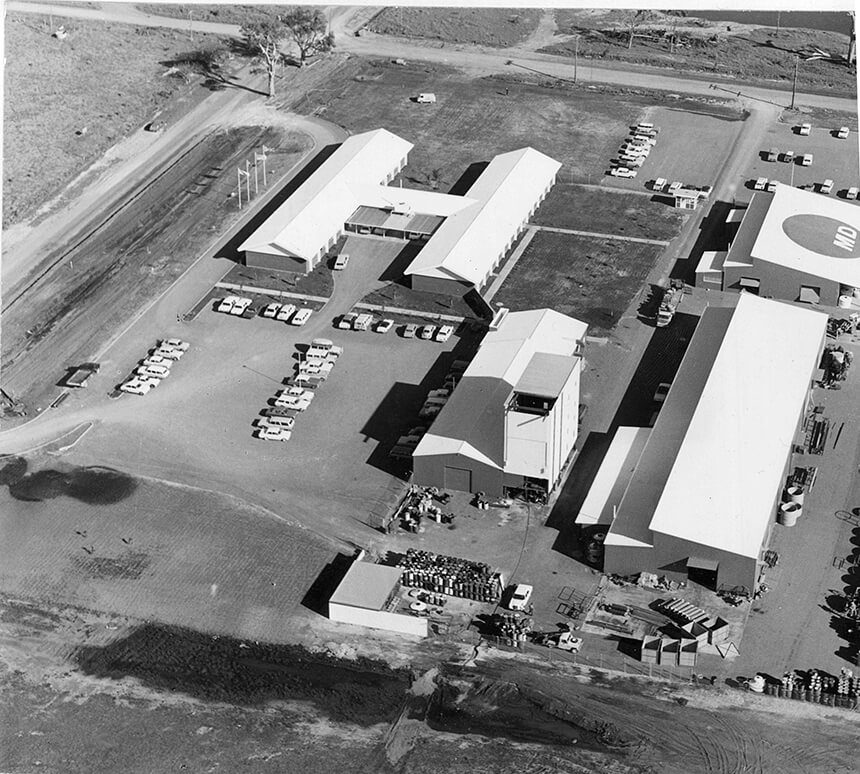

In 1970 MDL’s office, factory and metallurgical testing laboratory was relocated to Bundall and in 1971 its first overseas office was established in Denver, USA. This was followed by the establishment of an office in South Africa in 1973.

In 1979 MDL was purchased by United Mining Australia Limited (UMAL).

– Aerial View, New Bundall Head Office, 1970’s

– New Bundall Head Office, 1970s

1970s

State Government officials at Bridge Hill Ridge Plant led by NSW Minister for Mineral Resources and Development, Mr Ron Mulock with MDL’s Ecologist Dr John Lewis and Supervisor Mr Graeme Wells, 1979.

1980s

MDL expanded by relocating an existing plant to Bridge Hill Ridge in 1974 which operated successfully until 1983, having mined and processed over 130 million tonnes of mineral-bearing sands.

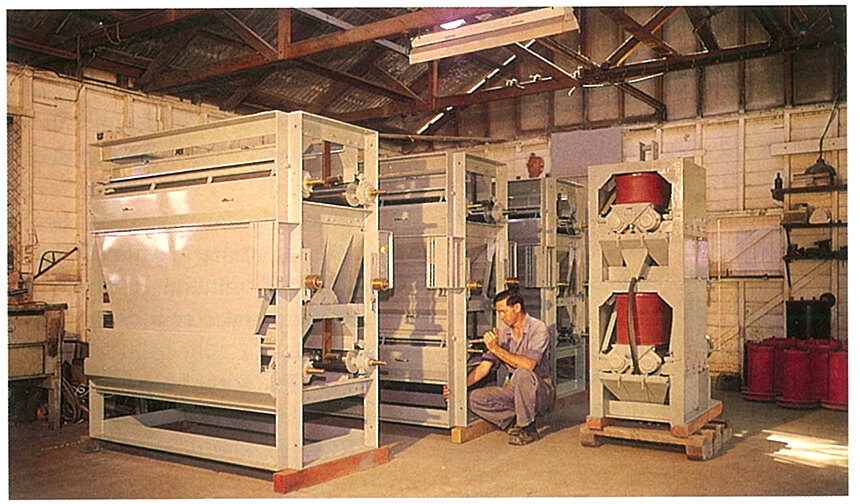

Purchased by BHP in 1984, MDL acquired new technologies and expertise including Doug Wright’s wash water-less spiral technology in 1985 and Vickers Fine Minerals Engineering Division in 1986.

New methods of spiral manufacture were developed incorporating reverse casting and solvent-less polyurethane spraying techniques.

– Trade show promotion, Las Vegas, USA, 1982

1980s

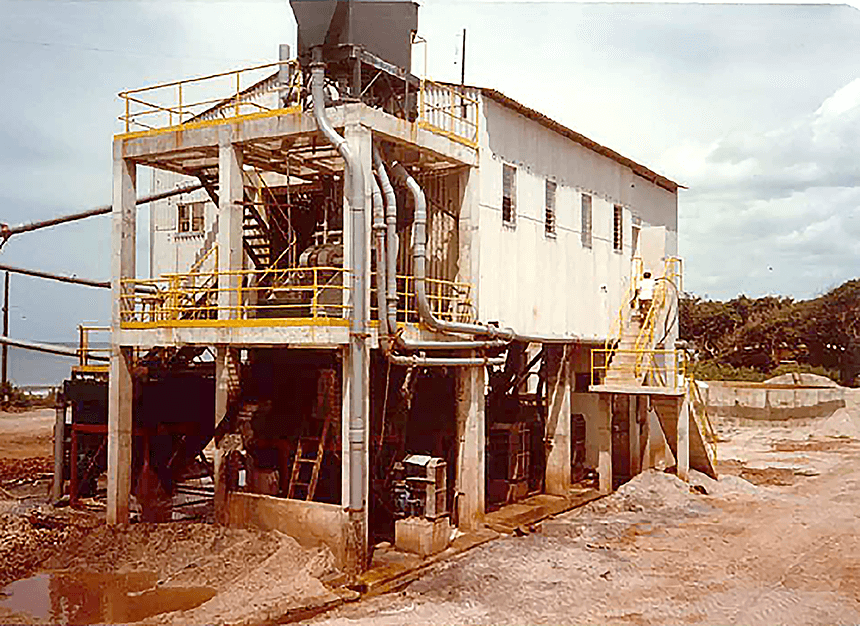

– Wet Gravity and Magnetic Separation Plant, Ceylon Mineral Sands, Sri Lanka, 1984

– Mineral Technologies employee Peter Haber commissioning work at Sierra Rutile, Sierra Leone, 1985

– Mt Newman Iron Ore Mine, WA, 1980s