Why it matters

Why it matters

Adapt ore lose

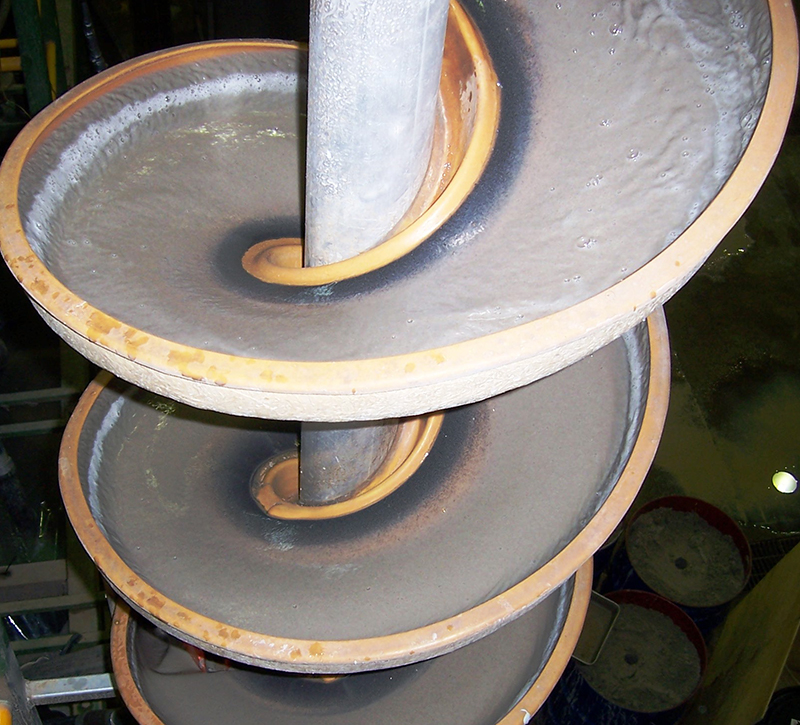

Chrome mining faces unique challenges, especially with spirals critical to beneficiation. High-density chromite ore complicates separation, causing inefficiencies and yield losses. Fine particles lead to clogging and reduced spiral effectiveness. Our advanced spirals, WHIMS, and Carrara HTR excel in durability, efficiency, and reliability, maximising production in a smaller space. Embrace the future of chrome mining with our innovative technologies, promising enhanced longevity, profitability, and maximised recovery rates.

Projects

Projects

Proven realworld success

Why it matters

Why it matters

Globalexpertise

From our beginnings in the 1940s separating fine minerals along Australia’s east coast, we have expanded to become the global leader in mineral sands processing. From Senegal’s largest mineral sands plant, Grande Côte, to Chemours on North America’s east coast, and numerous projects in Africa, India, Europe, and Australasia, our teams provide unmatched expertise in mineral sands processing throughout the project lifecycle.

Advantages

Advantages

You have the upper hand

- Achieves high fine chrome recovery and superior grade concentrates through innovative process solutions

- Offers robust spirals and WHIMS designed to withstand abrasive conditions, minimising downtime

- Provides tailored processing solutions to meet specific ore characteristics and operational needs

- Emphasises sustainable practices, including reduced water consumption and waste minimisation

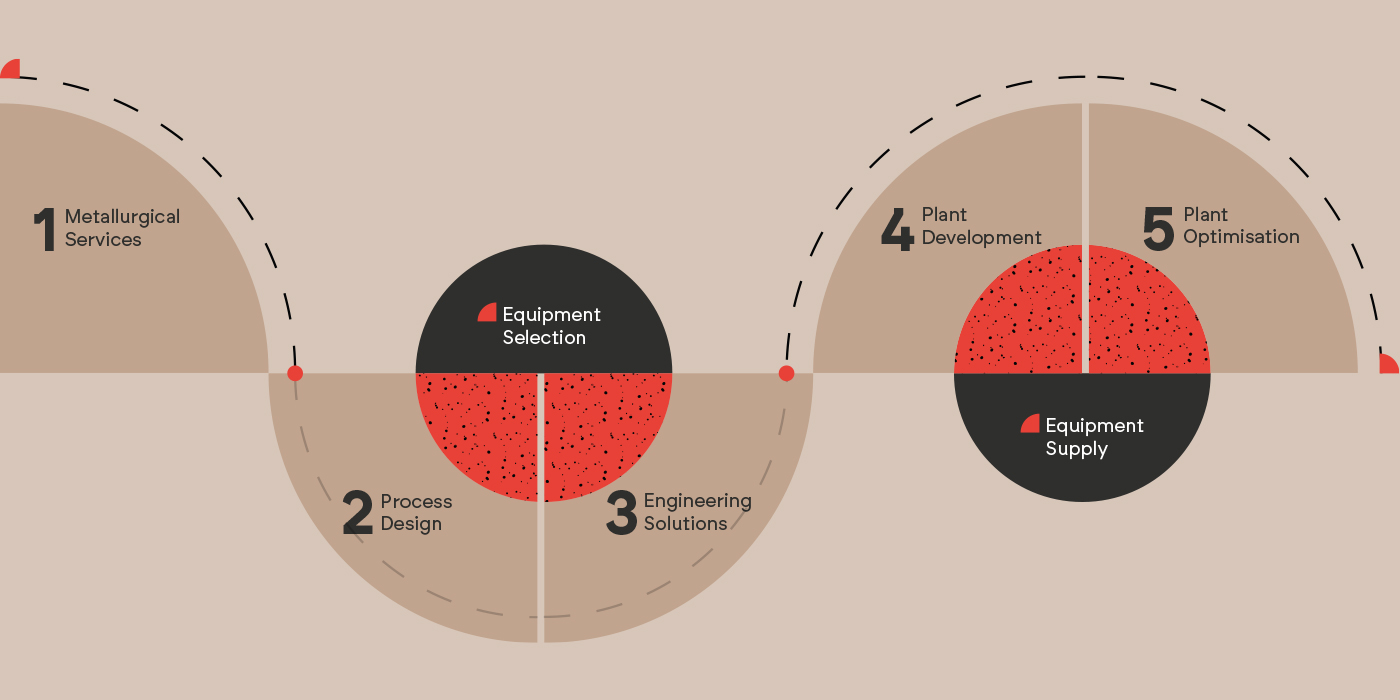

- Delivers end-to-end support, from mineral testing to plant commissioning and operational refinement

The thing with chrome is: You want to extract something that wears down your equipment in the long run. So make it as strong as possible.

– Stephan Van Staden

Business Unit Manager Africa

The Challenge

The Challenge

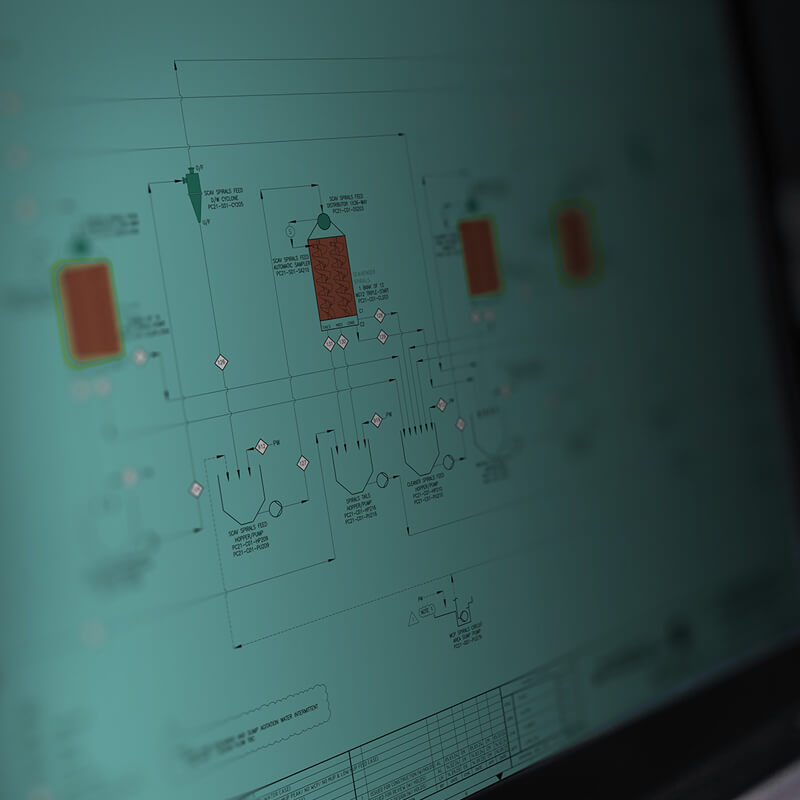

EarthFirst Approachto Chrome

From initial test work to final plant design, we provide concept, pre-feasibility, and feasibility studies along with cost-effective flowsheets for extracting mineral sands. Our process engineers excel in maximising the extraction of fine minerals, offering innovative solutions for unique ore bodies. We design plants capable of processing 5 to 7,000 tonnes per hour, incorporating gravity, electrostatic, and magnetic equipment. Our FlexSeries plants are modular and relocatable, offering customisable options for any mineral resource, ensuring high performance without compromising on cost or environmental standards.

Solutions

Solutions

Latest chromeequipment range

Our latest range of equipment built by decades of unmatched real world experience.

Stephan van Staden

Business Unit Manager Africa

Focus: Chrome

I love hands on problem solving with 22 years experience in chrome processing and optimisation.

The Expert

The Expert

ReachOut!

Ready to explore how our advanced solutions can revolutionise your chrome mining operations? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.