Why it matters

Why it matters

Enhancing efficiency and sustainability

We offer transformative processing solutions that boost efficiency and sustainability in mineral extraction. Our technologies enhance recovery rates across a broad particle size range, improve product grade through highly selective operations, and convert tailings into high-grade products. We enable significant water savings by up to 50%, and reduce power consumption. Our commitment to effective and sustainable mining practices enhances productivity and paves the way for a more sustainable future. Call us for fast, cost-effective solutions tailored to your needs.

Projects

Projects

Proven realworld success

Why it matters

Why it matters

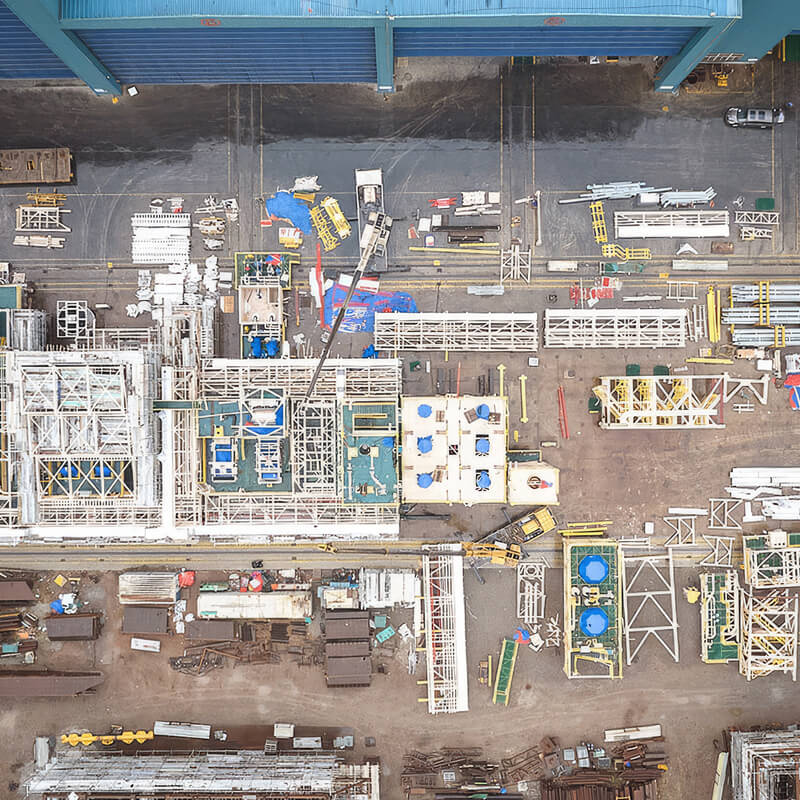

Globalexpertise

From our beginnings in the 1940s separating fine minerals along Australia’s east coast, we have expanded to become the global leader in mineral sands processing. From Senegal’s largest mineral sands plant, Grande Côte, to Chemours on North America’s east coast, and numerous projects in Africa, India, Europe, and Australasia, our teams provide unmatched expertise in mineral sands processing throughout the project lifecycle.

Advantages

Advantages

You have the upper hand

- Cost-Effective Installation: Compact, lightweight construction reduces installation expenses.

- High Reliability: Minimal maintenance requirements and high plant availability ensure continuous operation.

- Energy Efficiency: Advanced magnetic elements designed to lower energy consumption and operating costs.

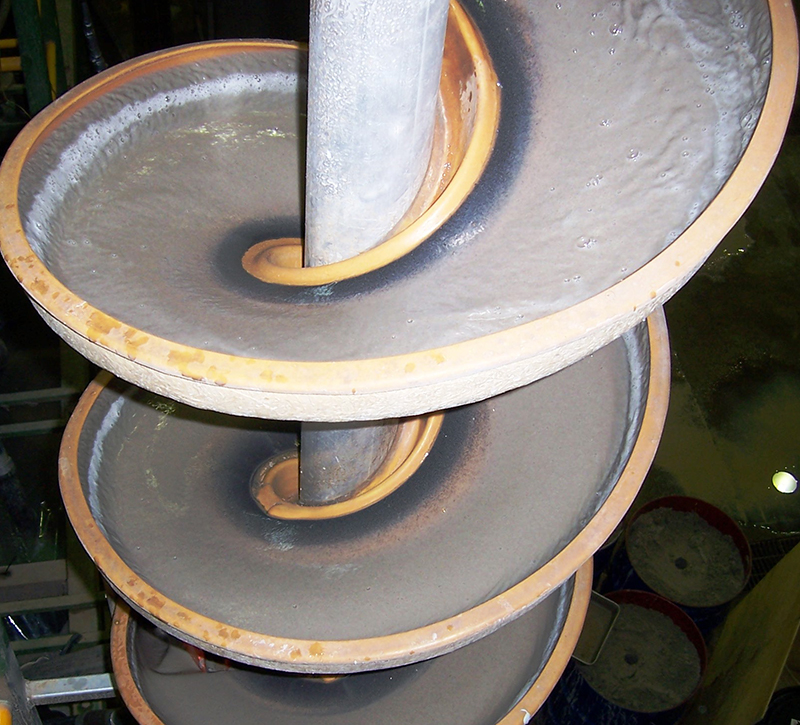

- User-Friendly Operation: Spiral equipment is simple to operate and does not require skilled labor.

- Built to Last: Our equipment features robust and proven designs for enhanced durability.

Over the past two decades or so, I've been engaged in nearly every project, minor and major, from a gravity equipment supply perspective. I can remember the timing, location, and approach taken, which proves highly advantageous when addressing new opportunities or resolving client challenges.

Shane Anderson

Product Manager Spiral Concentators

The Challenge

The Challenge

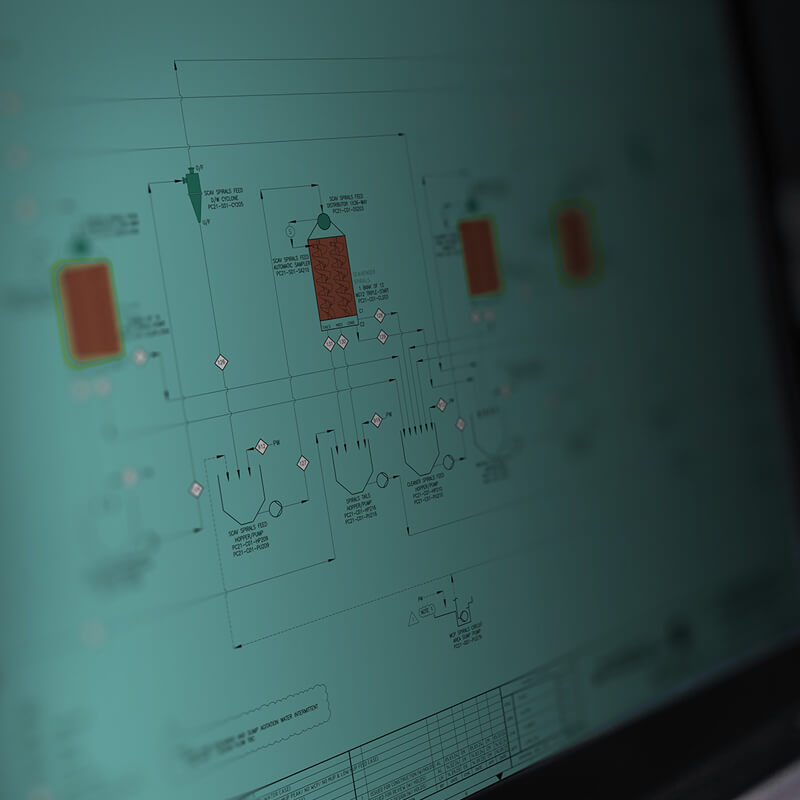

EarthFirst Approachto Mineral Sands

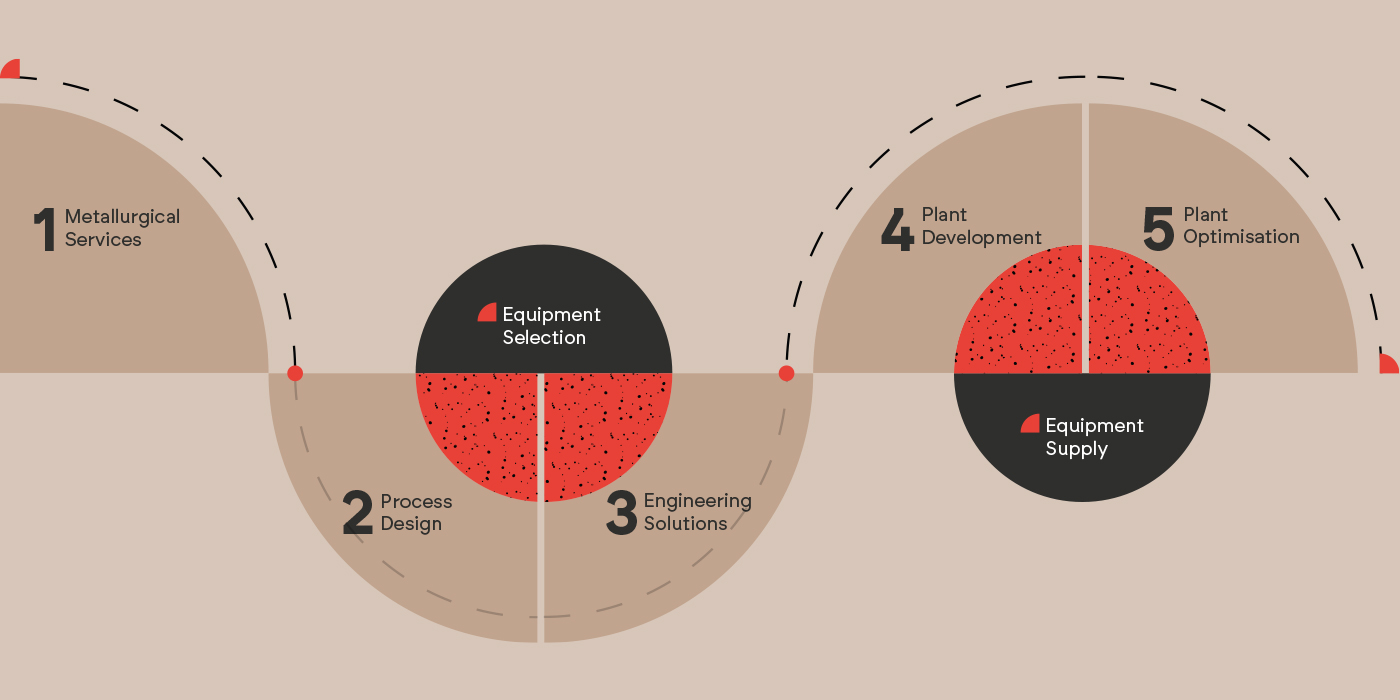

From initial test work to final plant design, we provide concept, pre-feasibility, and feasibility studies along with cost-effective flowsheets for extracting mineral sands. Our process engineers excel in maximising the extraction of fine minerals, offering innovative solutions for unique ore bodies. We design plants capable of processing 5 to 7,000 tonnes per hour, incorporating gravity, electrostatic, and magnetic equipment. Our FlexSeries plants are modular and relocatable, offering customisable options for any mineral resource, ensuring high performance without compromising on cost or environmental standards.

Solutions

Solutions

Latest mineral sandsequipment range

Our latest range of equipment built by decades of unmatched real world experience.

Matthew Allen

Global Manager – Business Development

Focus: Fine Minerals

I enjoy collaborating with a diverse range of individuals from various customer, competitor, and industry bodies. I have a passion for strategy and the process of developing plans with my team and putting those plans into action.

The Expert

The Expert

ReachOut!

Ready to explore how our advanced solutions can revolutionise your operations? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.