Industrial Minerals

Why it matters

Why it matters

Enhanced Solutions for Silica, Coal & Tin

We deliver cutting-edge mineral processing solutions across a wide range of industrial minerals and metals, including silica sand, coal, tin, and tungsten ores, as well as tailings re-processing. Our expertise enhances separation efficiencies while promoting sustainable practices.

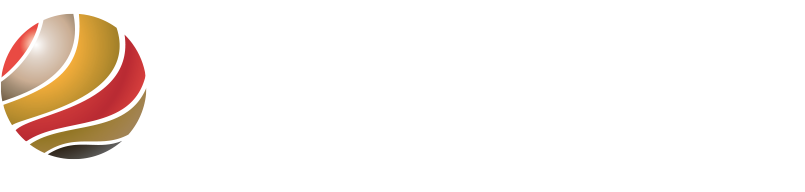

For silica sand, our metallurgical characterization, testing, and flowsheet development services ensure high recoveries, consistent product quality, and cost-effective processing. In coal processing, our globally recognized spiral designs maximize grades and recoveries, treating millions of tonnes of fine coal worldwide.

Projects

Projects

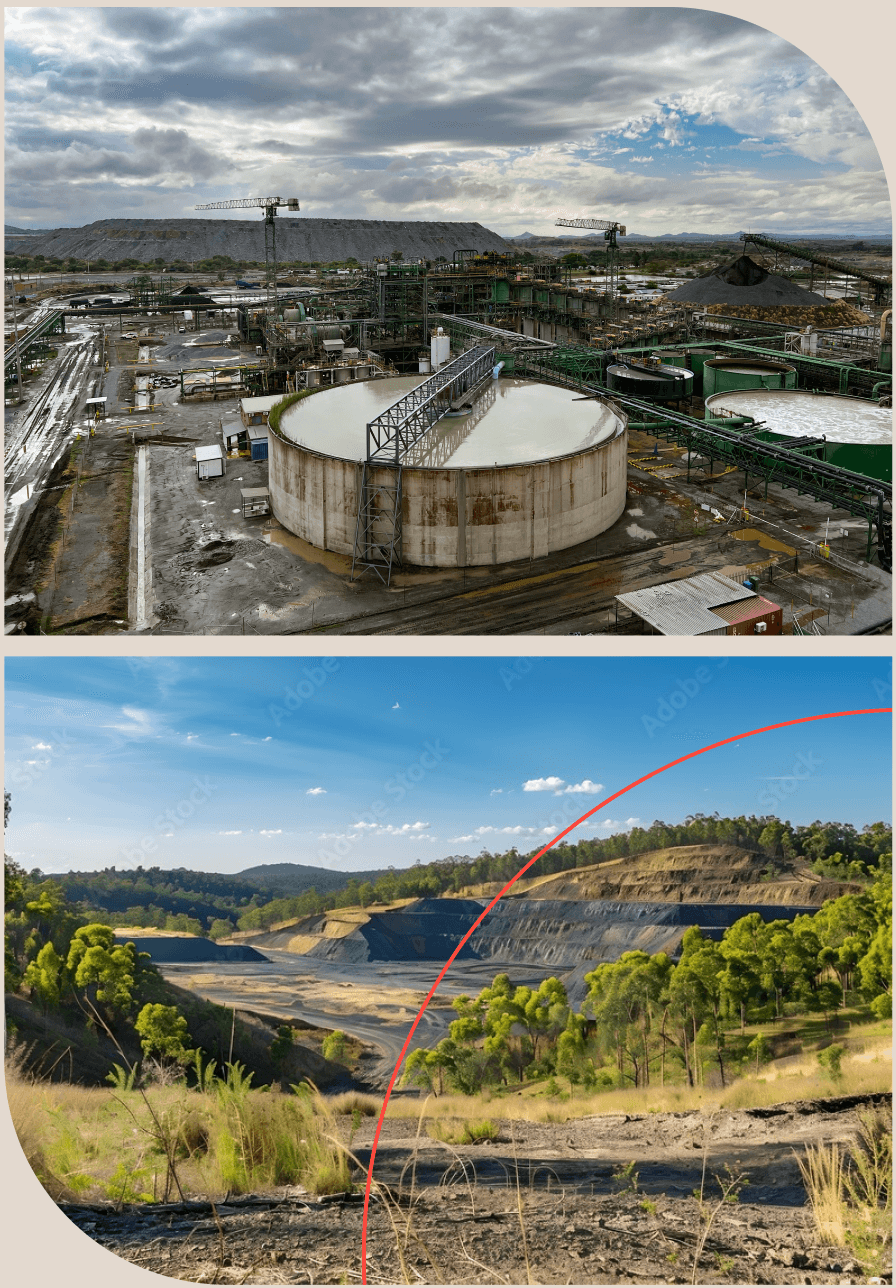

Proven real

world success

Why it matters

Why it matters

Global

Expertise

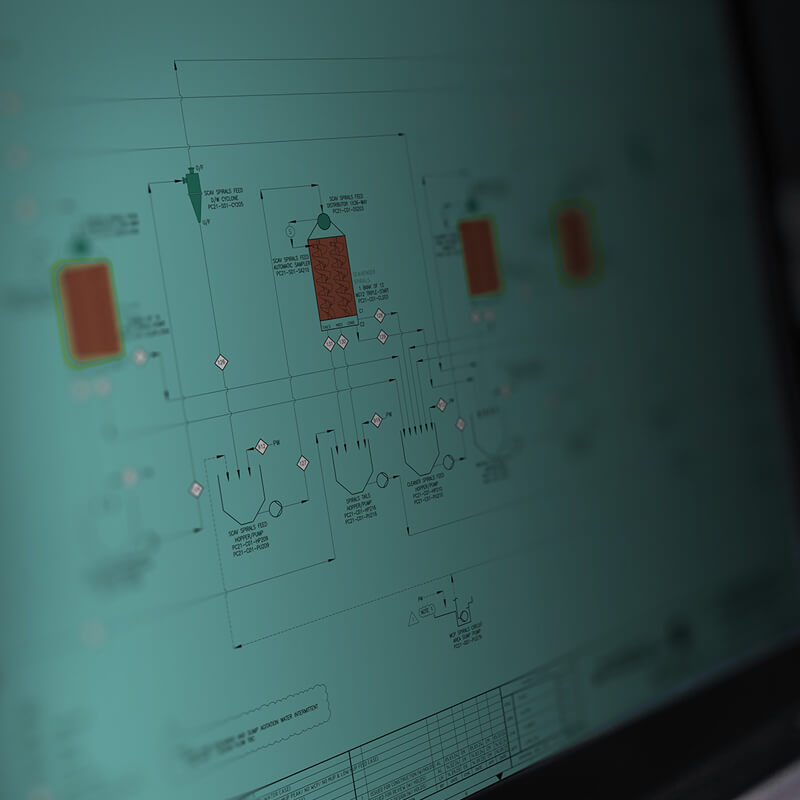

From our beginnings in the 1940s separating fine minerals along Australia’s east coast, we have expanded to become the global leader in mineral sands processing. From Senegal’s largest mineral sands plant, Grande Côte, to Chemours on North America’s east coast, and numerous projects in Africa, India, Europe, and Australasia, our teams provide unmatched expertise in mineral sands processing throughout the project lifecycle.

Backed by 80 years of experience, our proven technologies not only improve recoveries and product quality but also drive significant water and energy savings for more sustainable mining operations.

Advantages

Advantages

You have the upper hand

- Enhanced Recovery and Quality: Advanced processing solutions for superior recovery and grade of coal, silica sand, and tin.

- Robust Equipment Design: Durable spirals and separation technology tailored to withstand challenging conditions, reducing maintenance and downtime.

- Customised Processing: Solutions adapted to specific mineral characteristics and operational needs, ensuring optimal performance.

- Sustainable Practices: Focus on reducing water use and minimising waste, promoting environmentally responsible operations.

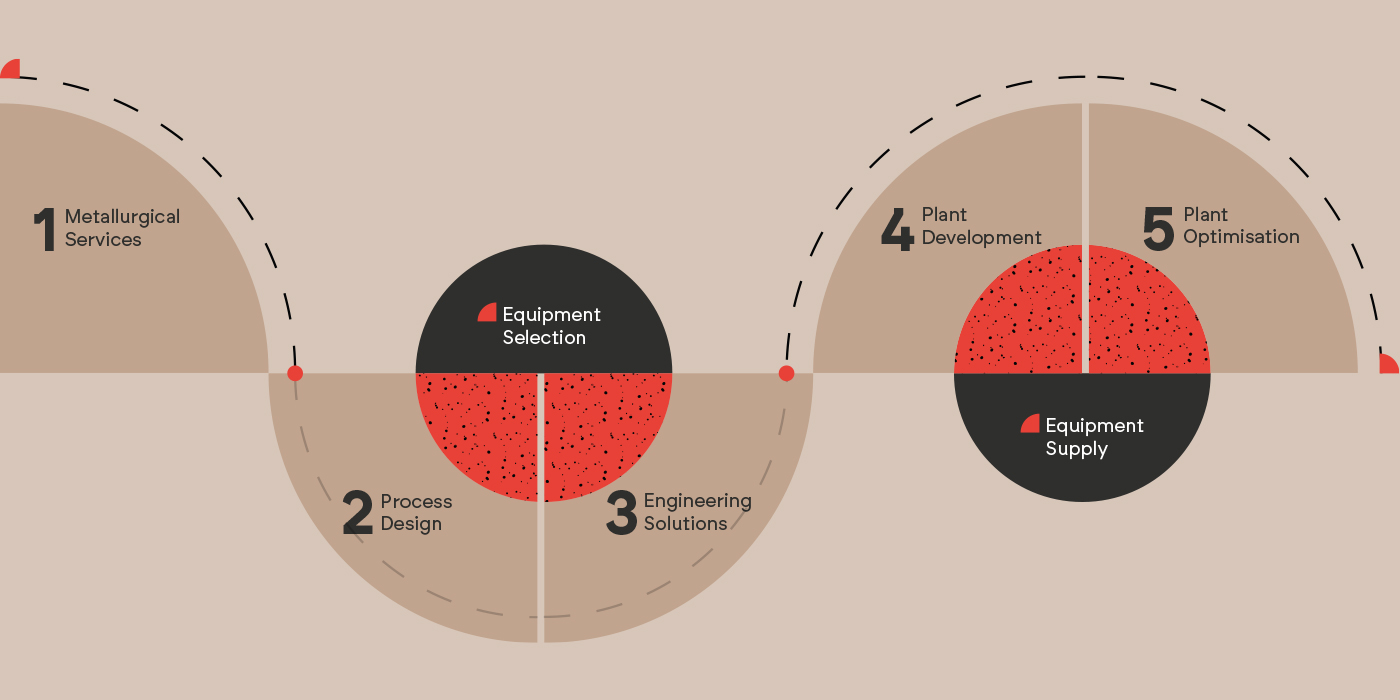

- Comprehensive Support: Full lifecycle support from mineral testing through to plant commissioning and ongoing operational refinement.

The Challenge

The Challenge

Earth First approach

to industrial minerals

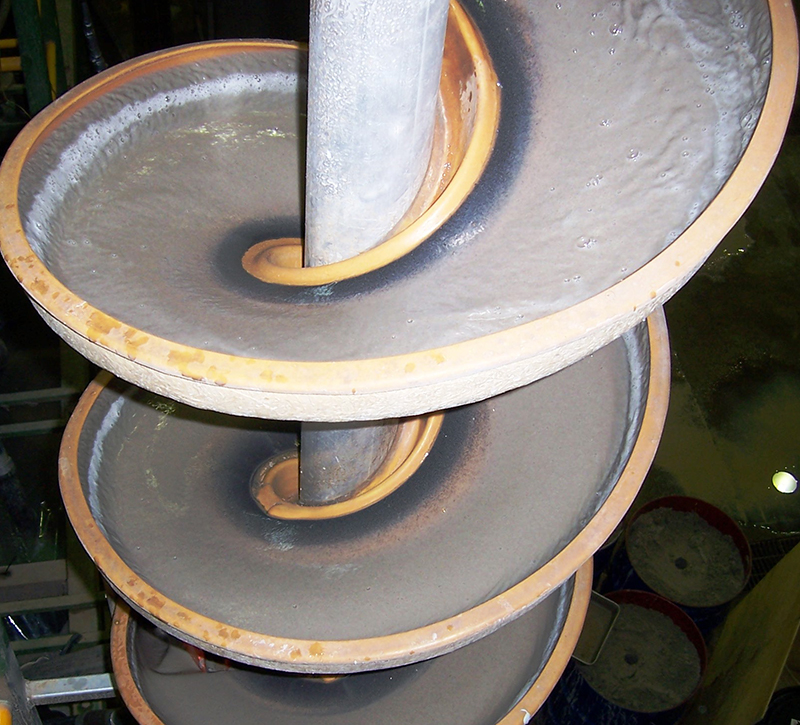

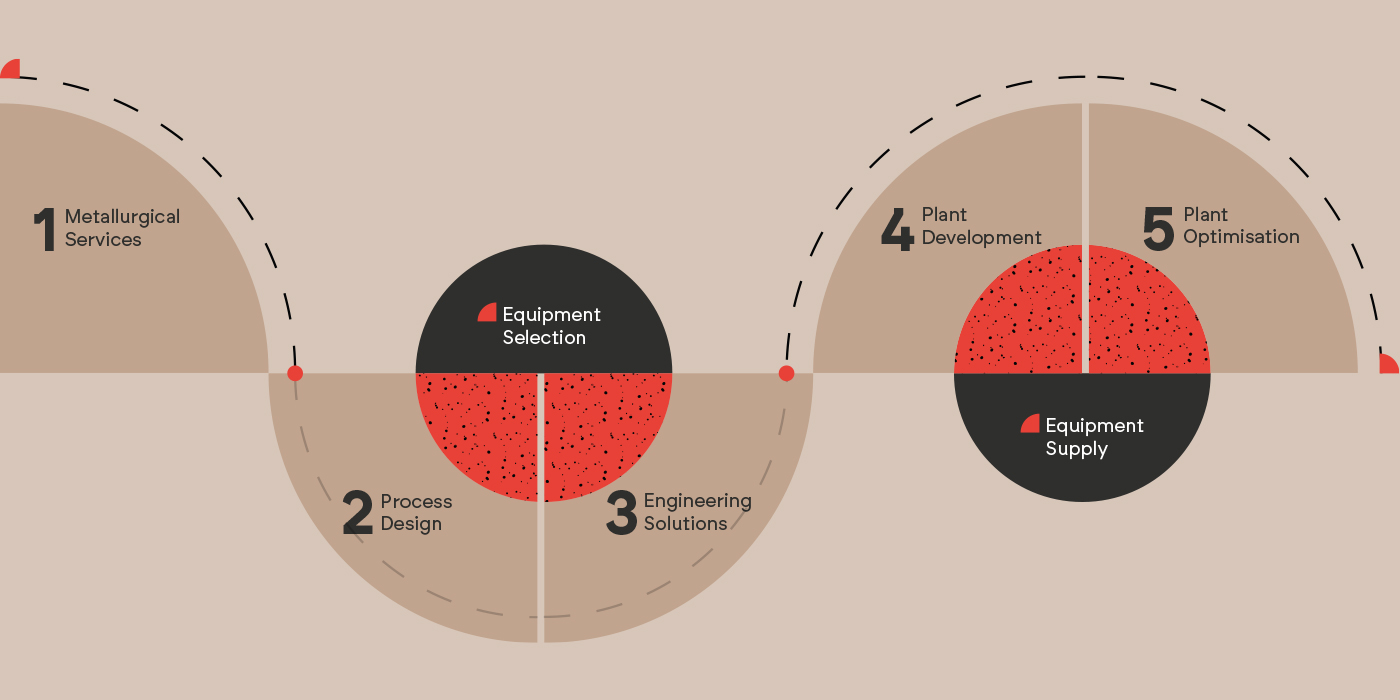

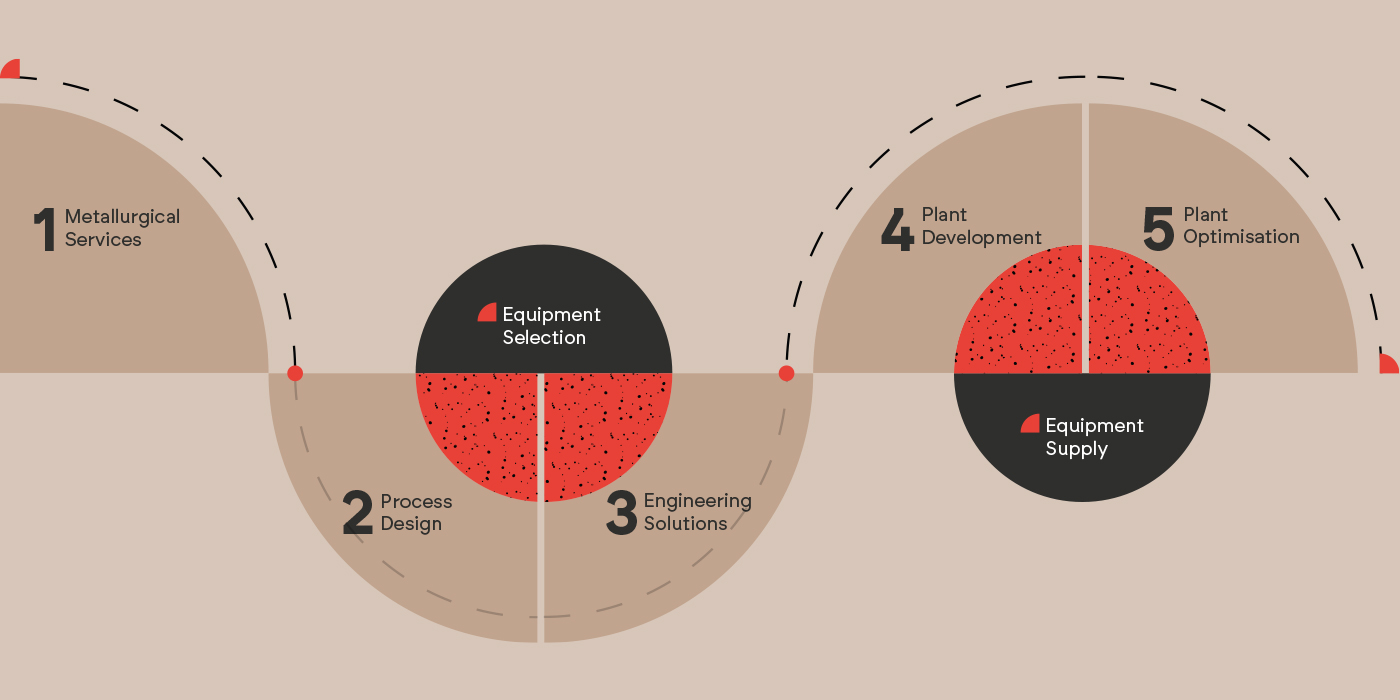

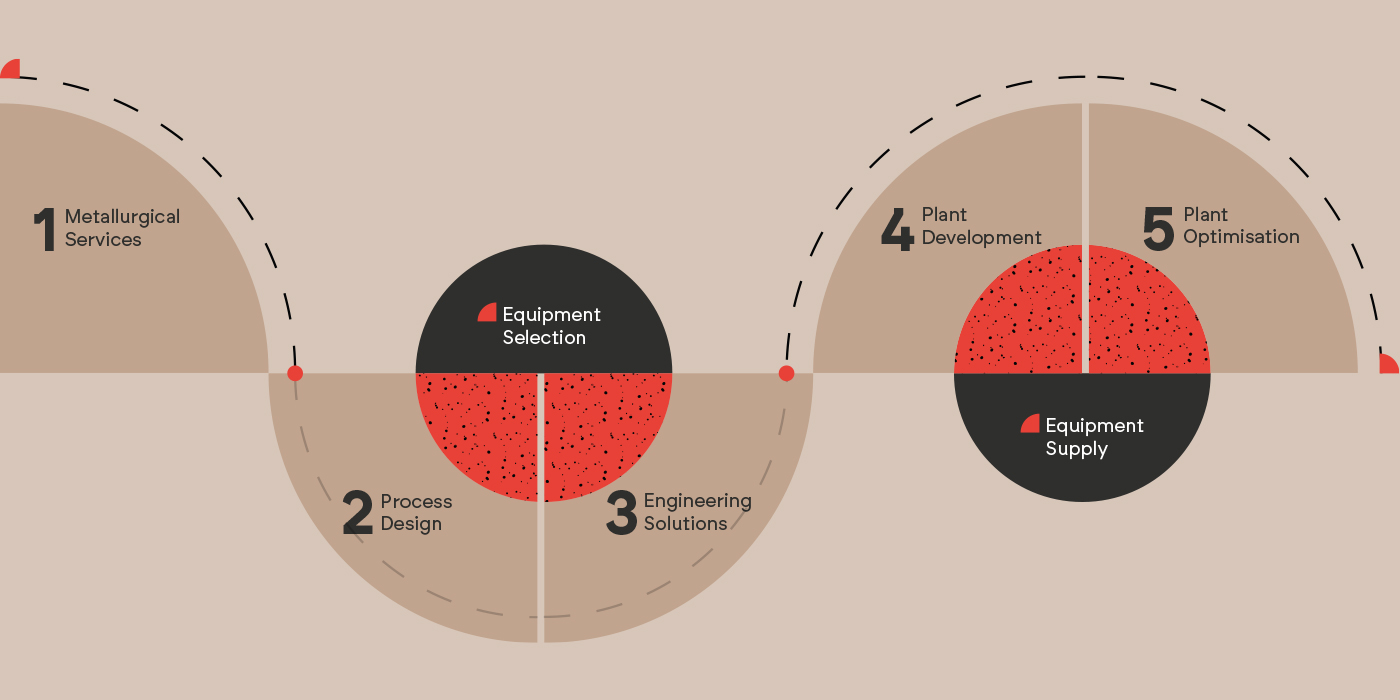

From initial test-work to final plant design, we provide concept, pre-feasibility, and feasibility studies along with cost-effective flowsheets for extracting industrial minerals. Our process engineers excel in maximising the extraction of fine minerals, offering innovative solutions for unique ore bodies. We design plants capable of processing 5 to 7,000 tonnes per hour, incorporating gravity, electrostatic, and magnetic equipment. Our FlexSeries plants are modular and relocatable, offering customisable options for any mineral resource, ensuring high performance without compromising on cost or environmental standards.

Solutions

Solutions

Latest industrial minerals

equipment range

Our latest range of equipment built by decades of unmatched real world experience.

Brenda Van Rhyn

Regional Manager – Australia

Focus: Fine Minerals Recovery

I am a results-driven chemical engineer, passionate about delivering innovative equipment solutions that maximize revenue while minimizing costs.

The Expert

The Expert

Reach

Out!

Ready to explore how our advanced solutions can revolutionise your industrial minerals operations? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.

Chrome

Why it matters

Why it matters

Adapt ore lose

Chrome mining faces unique challenges, especially with spirals critical to beneficiation. High-density chromite ore complicates separation, causing inefficiencies and yield losses. Fine particles lead to clogging and reduced spiral effectiveness. Our advanced spirals, WHIMS, and Carrara HTR excel in durability, efficiency, and reliability, maximising production in a smaller space. Embrace the future of chrome mining with our innovative technologies, promising enhanced longevity, profitability, and maximised recovery rates.

Projects

Projects

Proven real

world success

Why it matters

Why it matters

Global

expertise

From our beginnings in the 1940s separating fine minerals along Australia’s east coast, we have expanded to become the global leader in mineral sands processing. From Senegal’s largest mineral sands plant, Grande Côte, to Chemours on North America’s east coast, and numerous projects in Africa, India, Europe, and Australasia, our teams provide unmatched expertise in mineral sands processing throughout the project lifecycle.

Advantages

Advantages

You have the upper hand

- Achieves high fine chrome recovery and superior grade concentrates through innovative process solutions

- Offers robust spirals and WHIMS designed to withstand abrasive conditions, minimising downtime

- Provides tailored processing solutions to meet specific ore characteristics and operational needs

- Emphasises sustainable practices, including reduced water consumption and waste minimisation

- Delivers end-to-end support, from mineral testing to plant commissioning and operational refinement

The thing with chrome is: You want to extract something that wears down your equipment in the long run. So make it as strong as possible.

– Stephan Van Staden

Business Unit Manager Africa

The Challenge

The Challenge

EarthFirst Approach

to Chrome

From initial test work to final plant design, we provide concept, pre-feasibility, and feasibility studies along with cost-effective flowsheets for extracting mineral sands. Our process engineers excel in maximising the extraction of fine minerals, offering innovative solutions for unique ore bodies. We design plants capable of processing 5 to 7,000 tonnes per hour, incorporating gravity, electrostatic, and magnetic equipment. Our FlexSeries plants are modular and relocatable, offering customisable options for any mineral resource, ensuring high performance without compromising on cost or environmental standards.

Solutions

Solutions

Latest chrome

equipment range

Our latest range of equipment built by decades of unmatched real world experience.

Stephan van Staden

Business Unit Manager Africa

Focus: Chrome

I love hands on problem solving with 22 years experience in chrome processing and optimisation.

The Expert

The Expert

Reach

Out!

Ready to explore how our advanced solutions can revolutionise your chrome mining operations? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.

Mineral Sands

Why it matters

Why it matters

Enhancing efficiency and sustainability

We offer transformative processing solutions that boost efficiency and sustainability in mineral extraction. Our technologies enhance recovery rates across a broad particle size range, improve product grade through highly selective operations, and convert tailings into high-grade products. We enable significant water savings by up to 50%, and reduce power consumption. Our commitment to effective and sustainable mining practices enhances productivity and paves the way for a more sustainable future. Call us for fast, cost-effective solutions tailored to your needs.

Projects

Projects

Proven real

world success

Why it matters

Why it matters

Global

expertise

From our beginnings in the 1940s separating fine minerals along Australia’s east coast, we have expanded to become the global leader in mineral sands processing. From Senegal’s largest mineral sands plant, Grande Côte, to Chemours on North America’s east coast, and numerous projects in Africa, India, Europe, and Australasia, our teams provide unmatched expertise in mineral sands processing throughout the project lifecycle.

Advantages

Advantages

You have the upper hand

- Cost-Effective Installation: Compact, lightweight construction reduces installation expenses.

- High Reliability: Minimal maintenance requirements and high plant availability ensure continuous operation.

- Energy Efficiency: Advanced magnetic elements designed to lower energy consumption and operating costs.

- User-Friendly Operation: Spiral equipment is simple to operate and does not require skilled labor.

- Built to Last: Our equipment features robust and proven designs for enhanced durability.

Over the past two decades or so, I've been engaged in nearly every project, minor and major, from a gravity equipment supply perspective. I can remember the timing, location, and approach taken, which proves highly advantageous when addressing new opportunities or resolving client challenges.

Shane Anderson

Product Manager Spiral Concentators

The Challenge

The Challenge

EarthFirst Approach

to Mineral Sands

From initial test work to final plant design, we provide concept, pre-feasibility, and feasibility studies along with cost-effective flowsheets for extracting mineral sands. Our process engineers excel in maximising the extraction of fine minerals, offering innovative solutions for unique ore bodies. We design plants capable of processing 5 to 7,000 tonnes per hour, incorporating gravity, electrostatic, and magnetic equipment. Our FlexSeries plants are modular and relocatable, offering customisable options for any mineral resource, ensuring high performance without compromising on cost or environmental standards.

Solutions

Solutions

Latest mineral sands

equipment range

Our latest range of equipment built by decades of unmatched real world experience.

Matthew Allen

Global Manager – Business Development

Focus: Fine Minerals

I enjoy collaborating with a diverse range of individuals from various customer, competitor, and industry bodies. I have a passion for strategy and the process of developing plans with my team and putting those plans into action.

The Expert

The Expert

Reach

Out!

Ready to explore how our advanced solutions can revolutionise your operations? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.

Iron Ore

Why it matters

Why it matters

Upgrade to up grade

Mineral Technologies revolutionises iron ore extraction with technology that enhances efficiency and sustainability. We ensure maximum practical recoveries, enhance product grade, and transform tailings into high-grade products. Our commitment to processing excellence maximises product yield and supports sustainable mining practices for a better future.

Projects

Projects

Proven real

world success

Why it matters

Why it matters

Global

expertise

Mineral Technologies boasts 80+ years of history, beginning in the 1940’s in mineral sands processing in Queensland, Australia. The knowledge and separation technologies developed over the years can be directly applied to iron ore and leads to innovations in iron ore beneficiation that have been successfully used in other commodities. We develop process solutions to achieve high product yields & improved product grade from both fresh ore and tailings reclamation. From Canada to Australia, our experts deliver tailored solutions for optimal results.

The Challenge

The Challenge

Our approach

to iron ore

From test work to plant design, we deliver concept, pre-feasibility, and feasibility studies with cost-effective flowsheets for iron ore beneficiation. Our engineers maximise valuable product yield, drawing on our experience developing process flowsheets for projects around the world. Our designs incorporate gravity and magnetic separation equipment for 5 to 10,000 tonnes per hour, ensuring safe, efficient and reliable operation to maximise your project’s economics.

Solutions

Solutions

Iron ore

equipment range

Our latest range of equipment by decades of unmatched real world experience.

Ed Hart

Iron Ore Expert

Making a real difference to a project and enriching / improving the lives of others in some way. Enjoying the company of other like-minded people who work in our fantastic little company.

The Expert

The Expert

Reach

Out!

Ready to explore how our processing solutions can maximise your iron ore project? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.