Why it matters

Why it matters

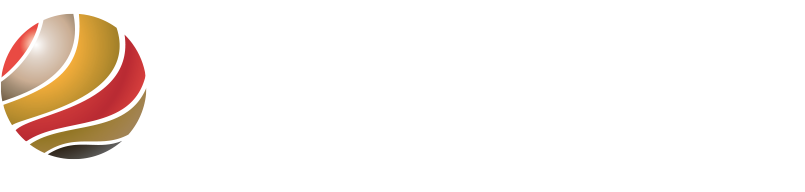

Designed for precision, built to last

Our magnetic separators deliver dependable, high-selectivity separation, enhancing recovery and product quality across all stages of the flowsheet.

In today’s complex mineral processing landscape, separating magnetic from non-magnetic materials is challenging, especially with fine particles and intricate ores. Traditional methods fall short, but our advanced technology ensures the flexibility and performance to exceed industry standards.

Technology

Technology

Advanced magnetic design

Our WHIMS are precisely engineered with an unparalleled density of dedicated magnetic coils per unit area, ensuring sharp mineral separation performance that stands unmatched in the industry.

Complementing this, our proprietary technology in salient plate design, generates an intense magnetic gradient, enabling the precise capture of a wide range of particle sizes. This focused magnetic intensity maximises mineral yield while minimising waste, setting a new standard in magnetic separation.

With continuous refinement and innovation, our WHIMS remain the benchmark for precision, efficiency, and reliability in the field.

Benefits

Benefits

The obvious choice

Complete Life Cycle support

We provide tailored programs, including Service Level Agreements (SLAs) and refurbishment or rotation options, ensuring your machines are expertly maintained for maximum uptime, reliability, and performance.

Built by the best

Our WHIMS systems are crafted by a team of skilled engineers, whose expertise and precision ensure unmatched reliability, performance, and quality trusted worldwide.

Quality above all

Quality parts only. While technology may improve around our fabrication techniques, we have always maintained a strict materials and fabrication standard.

Built to last

Engineered for endurance and designed to perform in the toughest conditions, our WHIMS technology is built to last, delivering reliable results and long-term value trusted by industries worldwide.

Dedication to the cause

Our dedicated, product-focused technical team ensures WHIMS technology is optimised for peak performance, delivering innovative, tailored solutions with unmatched precision and efficiency.

Global presence

Trusted worldwide, our extensive WHIMS installation base reflects reliability and industry confidence.

Features

Features

More than magnetic

Ensures near-perfect concentricity and durability under demanding conditions.

Featuring a fluted feed roller powered by a geared motor and variable frequency drive, our system offers precise feed control and seamless automated operation. With proven calibration techniques, it ensures accurate feeding across multiple machines.

Our superior salient plate, featuring a unique Mineral Technologies profile, is engineered to enhance magnetic gradient intensity. This innovative design ensures optimal particle capture across a wide size range, setting a new standard in performance and efficiency.

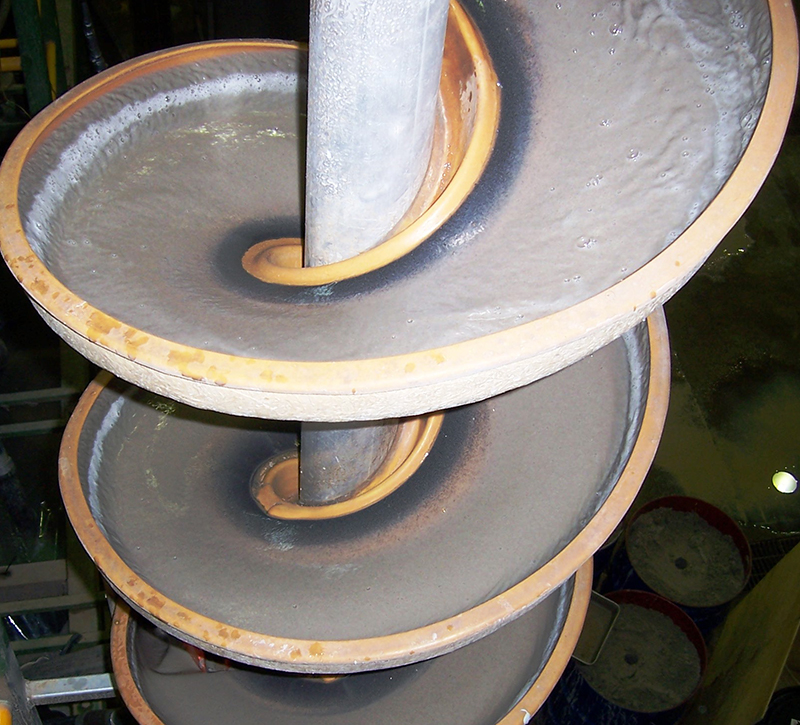

Our advanced control system uses modern protocols for seamless integration into both existing and new plants, with remote support options ensuring optimal performance and minimal downtime.

MT Readingsby the numbers:

20%

improved recovery through product refinement & R&D activities over the years

100+

successful refurbishments globally

120+ years

of combined product focused experience in our core product team

40+ years

our magnetic separators are built to last and perform for ages!

Magnetics

Magnetics

More tools in the box

The WHIMS (Wet High Intensity Magnetic Separator) is used for separating fine, weakly magnetic minerals like hematite from mineral sands. They are also effective and commonly used in upgrading iron ore fines.

Rare Earth Drum Magnetic Separators (REDs) are widely used in the minerals processing industry for separating highly paramagnetic minerals like ilmenite, garnet, and chromite. They enhance recovery rates and improve product purity by efficiently removing magnetic impurities.

RERs concentrate dry and free flowing granular particles. Typical applications include production of Ilmenite, Chromite and hematite concentrates. (good at fractionizing)

The IRMS is designed for optimal magnetic field strength and adaptability, efficiently separating weakly magnetic particles, including those with (close in magnetic) magnetic properties like monazite and garnet.

The LIMS is designed for processing strongly magnetic minerals such as magnetite. It delivers dependable separation in coarse and fine iron ore applications, providing essential support in the early stages of mineral processing for high recovery rates and consistent product quality.

Nicolas Boonzaier

Product Manager Lyons Unit, Magnets

Focus: Advanced fines processing equipment

The Expert

The Expert

ReachOut!

Ready to explore how our magnetic separation solutions can transform your operations? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.

Get detailed Insights

Get detailed Insights

Success Stories

Explore how our metallurgical testing expertise has driven success for global projects. From mineral sands in Australia to complex tailings reprocessing globally, our solutions deliver measurable results.