Why it matters

Why it matters

Effective fines separation - in a single pass

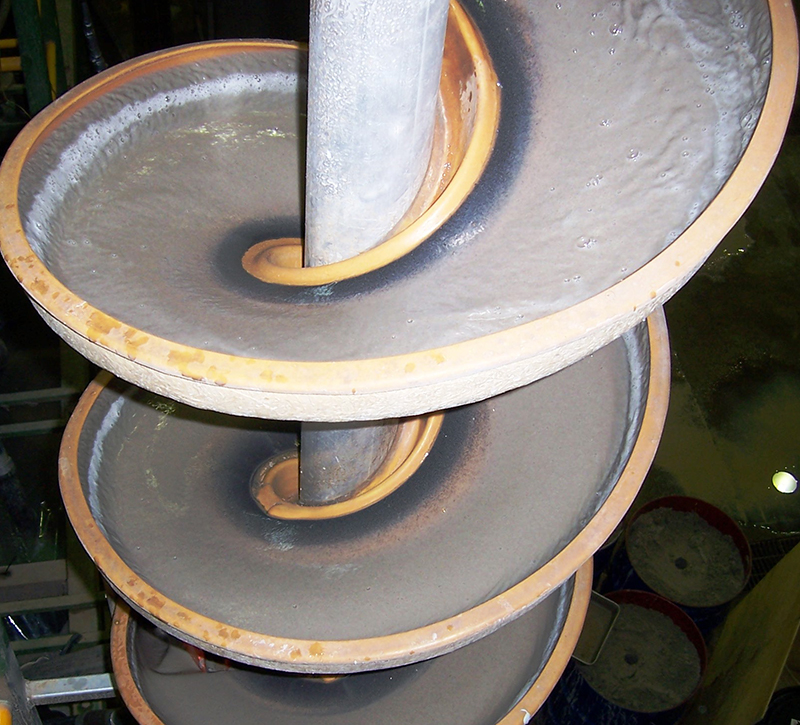

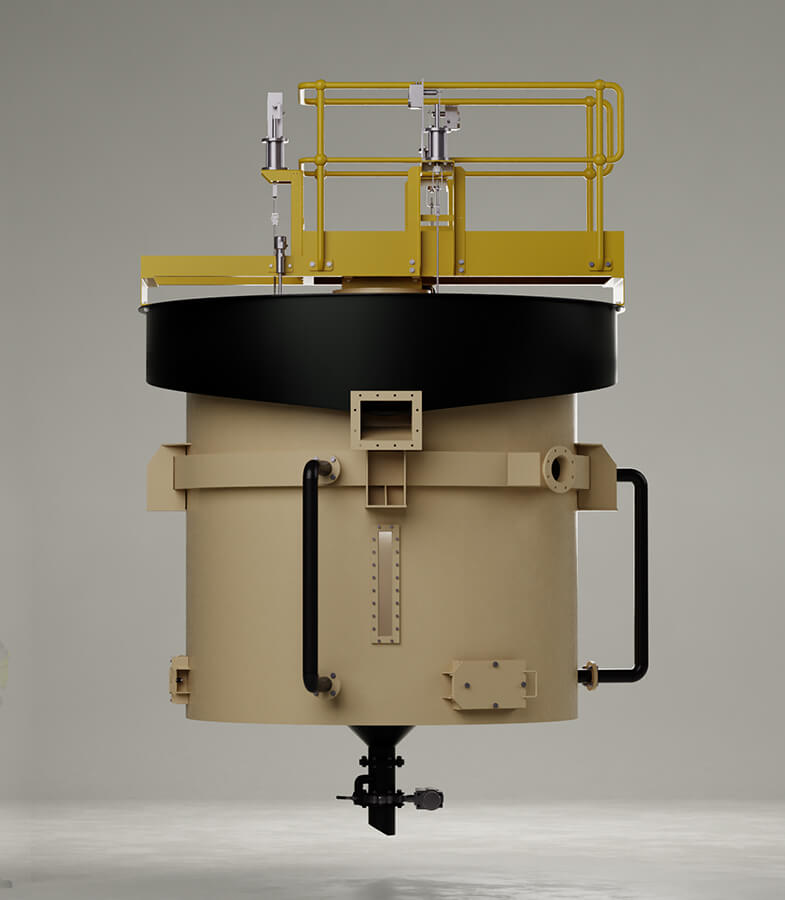

The MT Teeter Bed Separator (TBS) is designed for fine particle classification based on size and density, if applied correctly, can replace the need for multiple spiral circuits, saving time and money and space within your plant. Using water to fluidize and closely control a bed of particles, the TBS delivers sharp separations, higher recoveries, and improved product quality across coal, mineral sands, and industrial mineral applications.

How it Works

How it Works

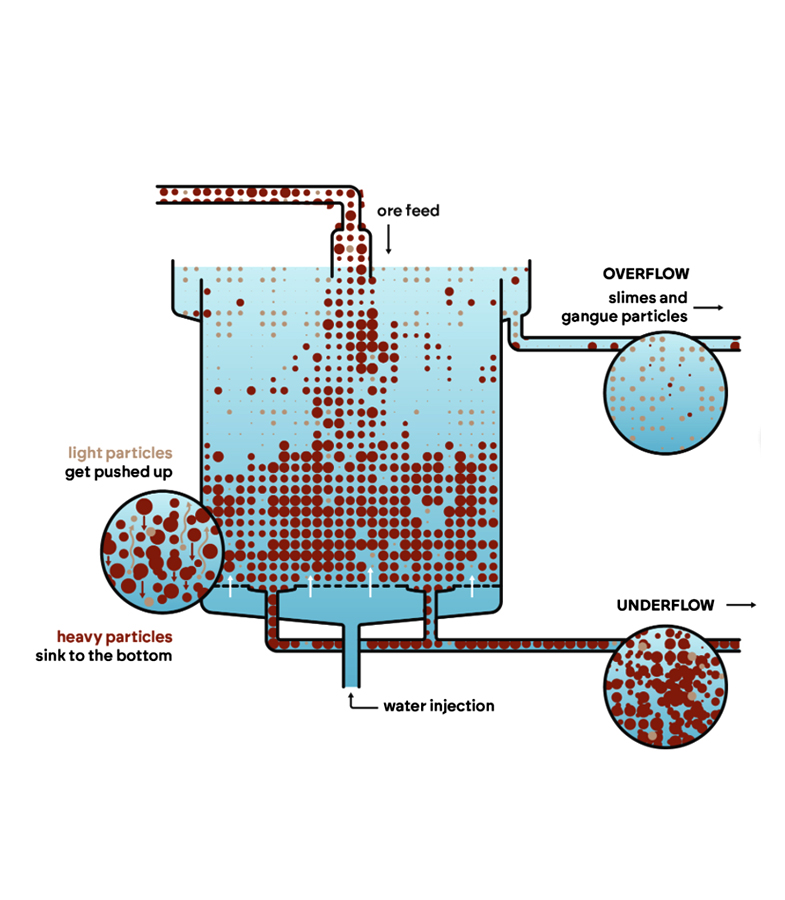

How the Teetered Bed Separator Delivers Efficient Density Separation.

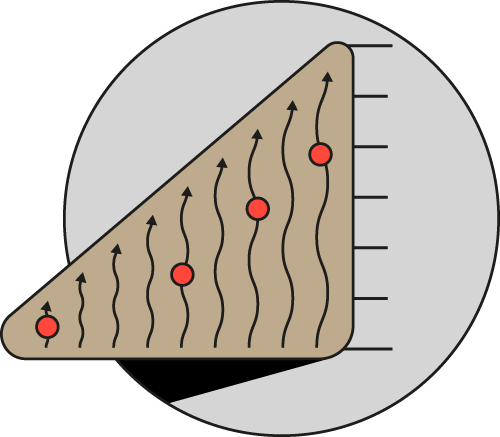

The feed enters the TBS through a central feed well that distributes slurry evenly across the unit without disturbing the teeter bed. Inside the separator, coarse and dense particles settle to form the bed, while fine and lighter particles rise and report to the overflow launder.

A network of specialised teeter water nozzles keeps the bed fluidised, allowing fine and light particles trapped within the bed to elutriate upward and exit with the overflow. The underflow consists of the denser, coarser particles and is discharged in a controlled manner.

Bed density is automatically regulated by adjusting the underflow valve, ensuring stable operation and consistent separation performance.

Effective Separation

Effective Separation

Proven Technology. Made in Australia.

Backed by over 60 installations worldwide, the Australian-engineered TBS has proven it’s reliability globally since 2005. With a standard range of sizes to meet smaller operations, or larger throughputs upward of 300 tph.

| Sizes (Diameter) | Capacity (t/h) |

|---|---|

| 1.5 m | 40-45 |

| 1.8 m | 60-70 |

| 2.1 m | 80-90 |

| 2.4 m | 100-120 |

| 3.0 m | 170-180 |

| 3.65 m | 260-270 |

| 4.0 m | 310-320 |

This table is for indicative purposes only – final sizing must be confirmed based on the particle size distribution and material density specific to the operation.

Benefits

The result is a separator that not only classifies, but also enhances process efficiency and product consistency – making it a critical enabler of outcome certainty in modern mineral processing plants.

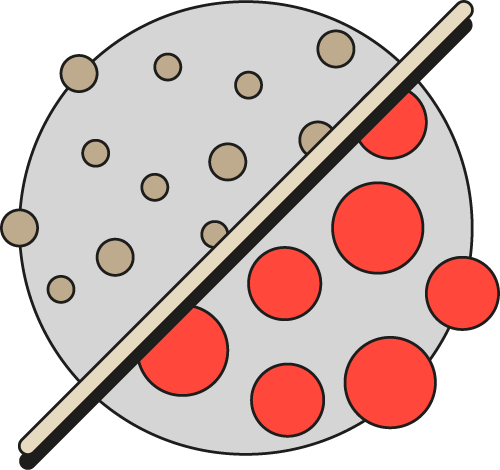

Controlled hindered settling

Particles interact within the fluidized bed, improving cut accuracy and minimizing misplaced material.

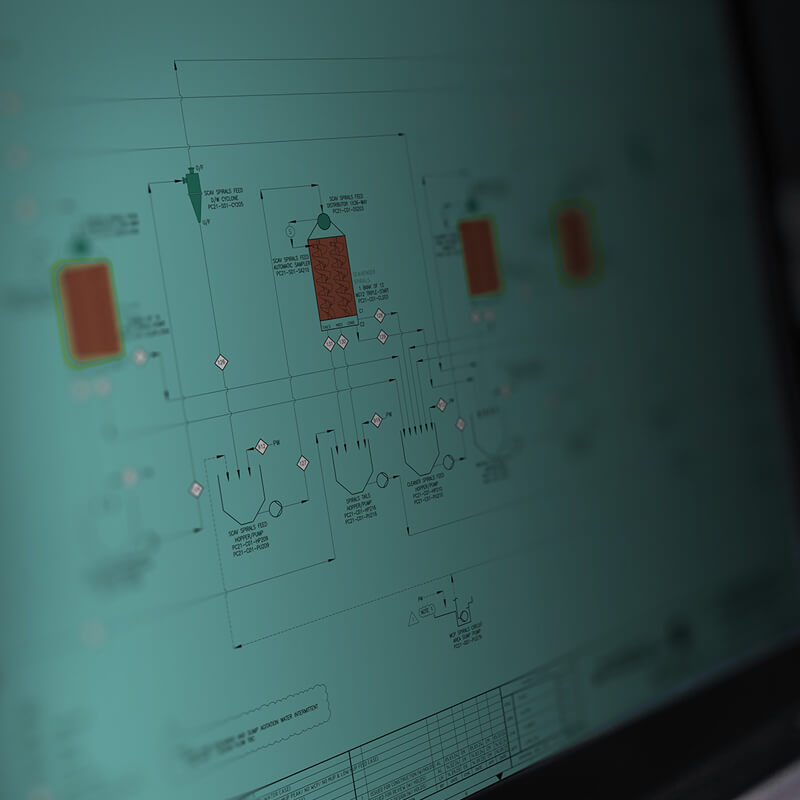

Dynamic bed pressure management

Sensors measure teeter bed density in real time, adjusting automatically to feed fluctuations for stable performance.

Sharper cut points

Unlike basic classifiers that struggle with fine or near-density material, the TBS achieves a sharper separation curve, improving product quality and recovery.

Engineered for durability

Proven material selection ensures over 10 years of performance in high-wear zones.

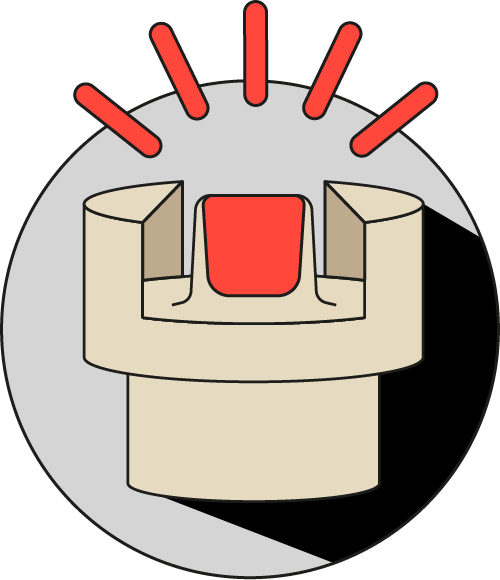

Unique Nozzle Design

Allows for one way water flow preventing seepage of unwanted solids into the water chamber.

Applications

The MT Teeter Bed Separator is used across multiple industries where fine particle separation is critical.

Coal Preparation

Efficiently separates high-ash from clean coal.

Mineral Sands

Upgrades heavyminerals and rejects lighter gangue.

Industrial Minerals

Provides sharp density-based classification.

Base Metals

Acts as a pre-concentration stage ahead of flotation.

Frequently asked questions

Our TBS features a unique self-closing nozzle insert that ensures even water distribution and prevents back-seepage into the teeter water chamber, maintaining consistent fluidisation and reducing maintenance.

Depending on the duty and material characteristics, we use either dart valves or pinch valves to provide precise underflow control and reliable operation across a wide range of particle sizes and densities.

Yes. While we offer a standard instrumentation package, we can customise components to align with your site standards or project requirements.

Absolutely. We have field service and process specialists located globally who can assist with installation, commissioning, and performance optimisation.

With proper operation and maintenance, TBS units typically achieve a service life exceeding 20 years, delivering long-term reliability and value.

Nicolas Boonzaier

Product Manager: Mechanical Equipment

Focus: Advanced fines processing equipment

The Expert

The Expert

ReachOut!

Ready to explore how our advanced technology can revolutionise your operations? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.