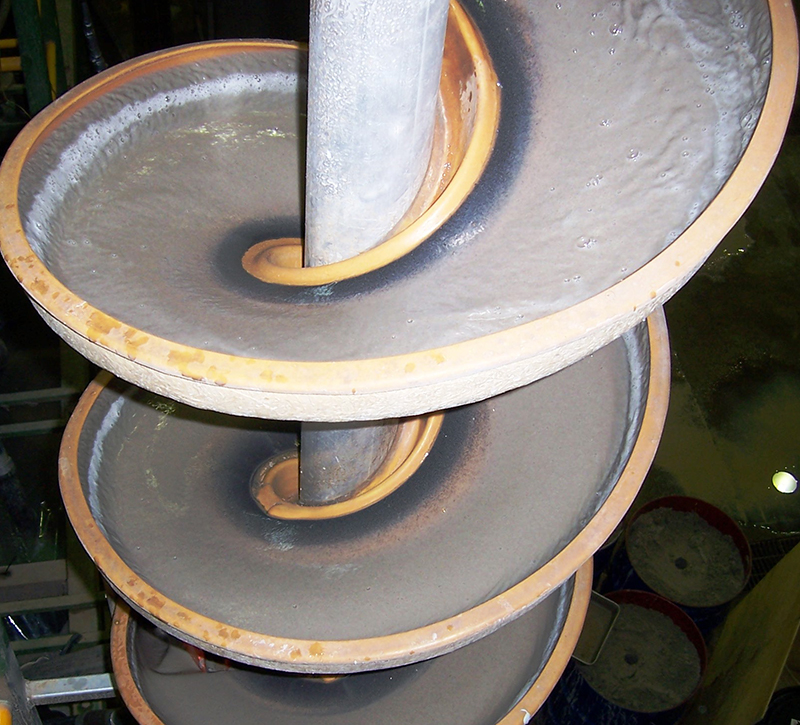

Projects

Proven Success in Global Mineral Processing – Transforming Vision into Reality.

At Mineral Technologies, our track record of successful projects spans the globe. From concept to completion, we partner with clients to deliver innovative, tailored solutions that exceed expectations. Explore our portfolio and see how we turn challenges into opportunities, ensuring success in every phase of your project.