Why it matters

Why it matters

Future proof

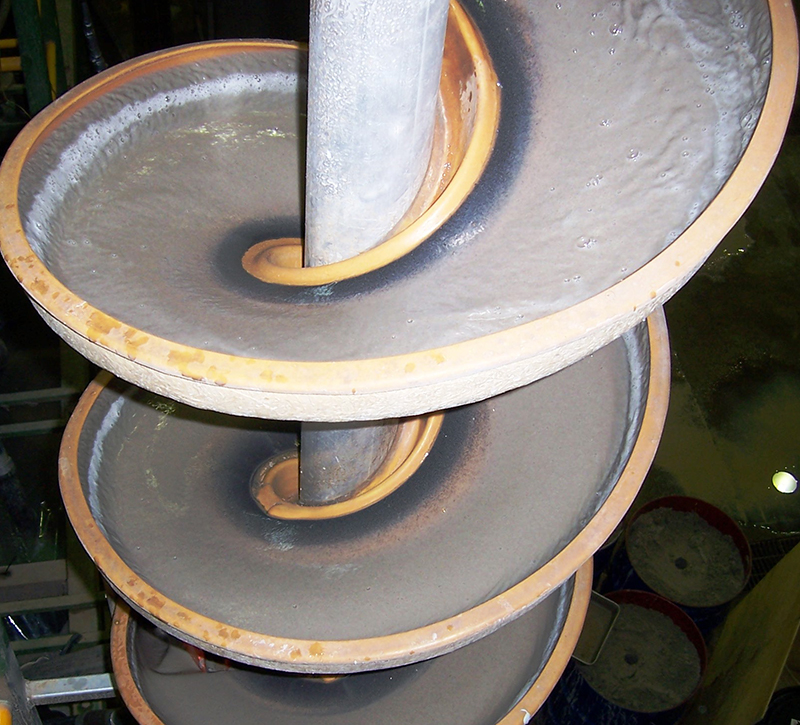

With over 80 years of expertise in high-yield, cost-effective, and sustainable mineral sands solutions. Our end-to-end services, from testing to support, include innovative technologies like our Spirals, Lyons Unit and WHIMS for efficient extraction of valuable minerals.

Committed to responsible mining, we strive to minimise environmental impact. Our approach maximises yield, future-proofs mines, and boosts investor confidence in sustainable, profitable mineral sands projects.

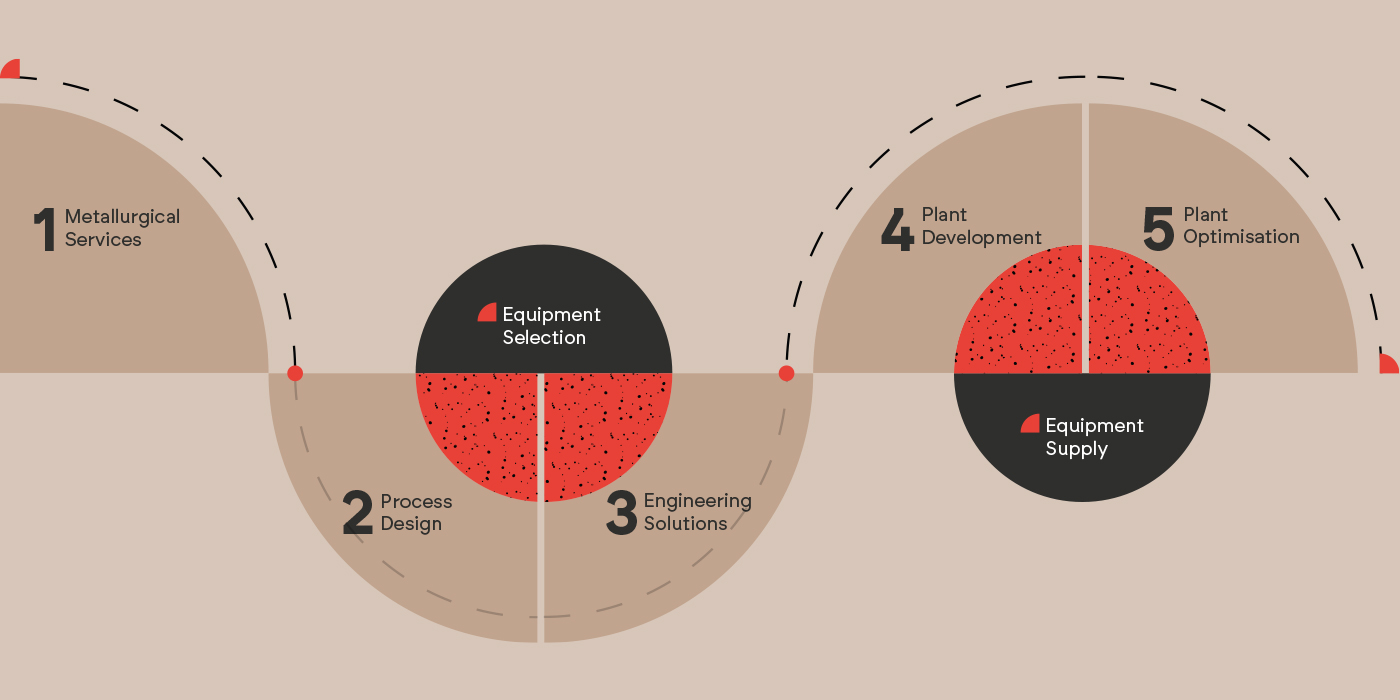

Approach

Approach

One stop shop

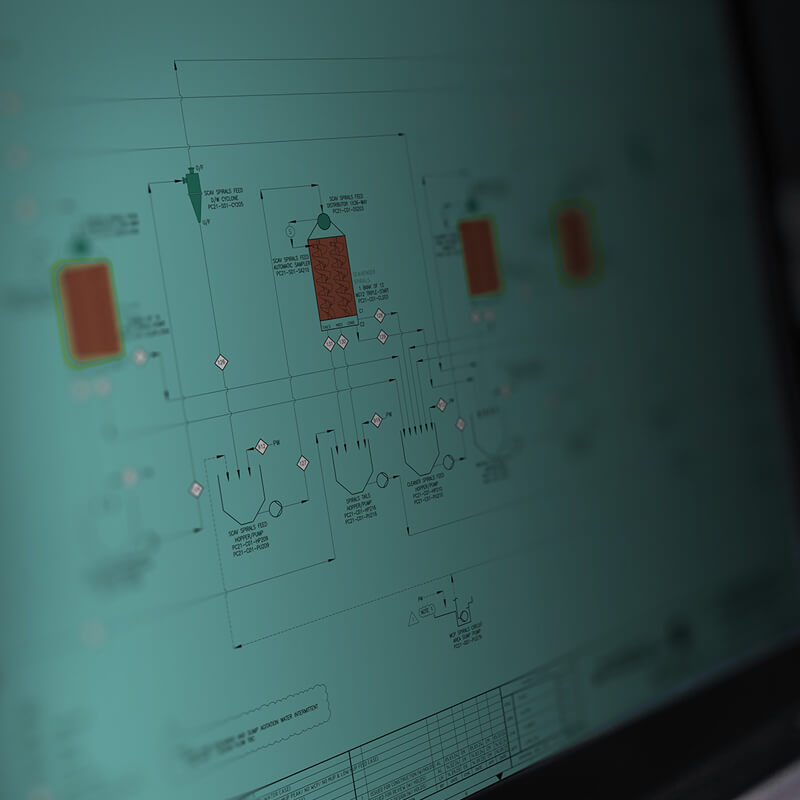

No two ore bodies are the same. Our process engineers begin with exploring and interrogating mineral sands processing solutions utilising testwork programs specifically designed to maximise the extraction of ilmenite, rutile, zircon and other fine minerals.

From our testwork we deliver concept, prefeasibility and feasibility studies as well as cost effective flowsheets to safely and efficiently extract the fine minerals. We then continue to work with customers through project lifecycles to deliver ongoing support and processing expertise to ensure project goals are achieved. The following figures are our benchmarks.

The Challenge

The Challenge

Latest mature technology

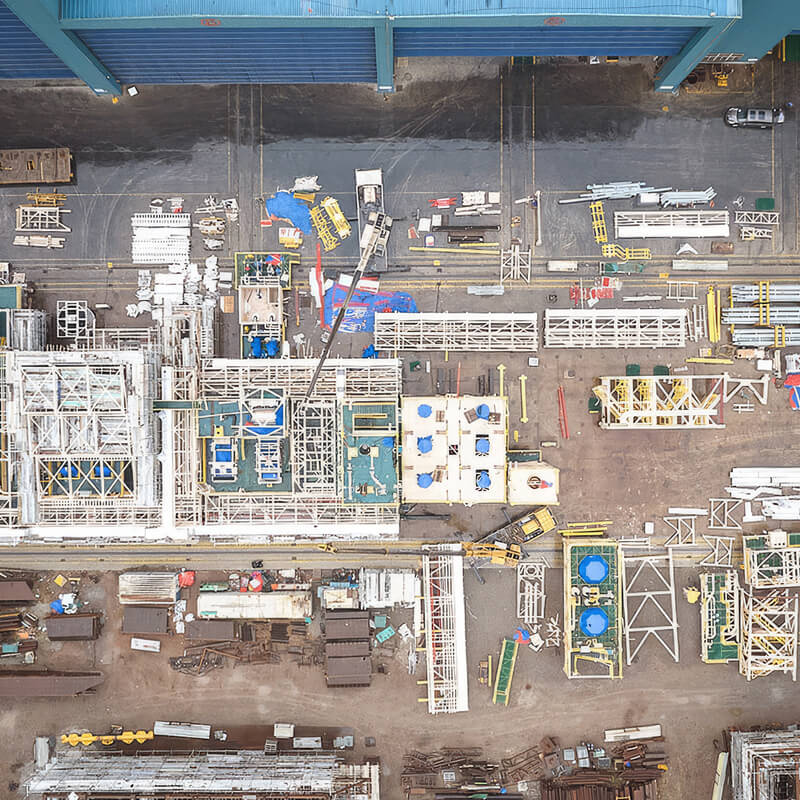

Marginal deposits and complex ores present formidable obstacles in mineral sands processing. Traditional methods often fall short, leaving valuable resources untapped and increasing environmental footprints. The industry grapples with rising costs, stringent regulations, and the pressing need for sustainable practices. Without innovative solutions, we risk missing out on critical minerals essential for green technologies and economic growth, while potentially causing unnecessary harm to our planet.

Our Solution

Our Solution

Proven precision globally

Our comprehensive approach revolutionises mineral sands processing. We offer a seamless journey from initial testing to plant design and operation, all under one roof. Our cutting-edge technologies, like the MG12 spirals and HTR400 separator, maximise recovery while minimising waste. By tailoring solutions to each unique deposit, we unlock the full potential of mineral sands, ensuring efficient extraction and processing. This not only boosts profitability but also reduces environmental impact, paving the way for a more sustainable mining future.

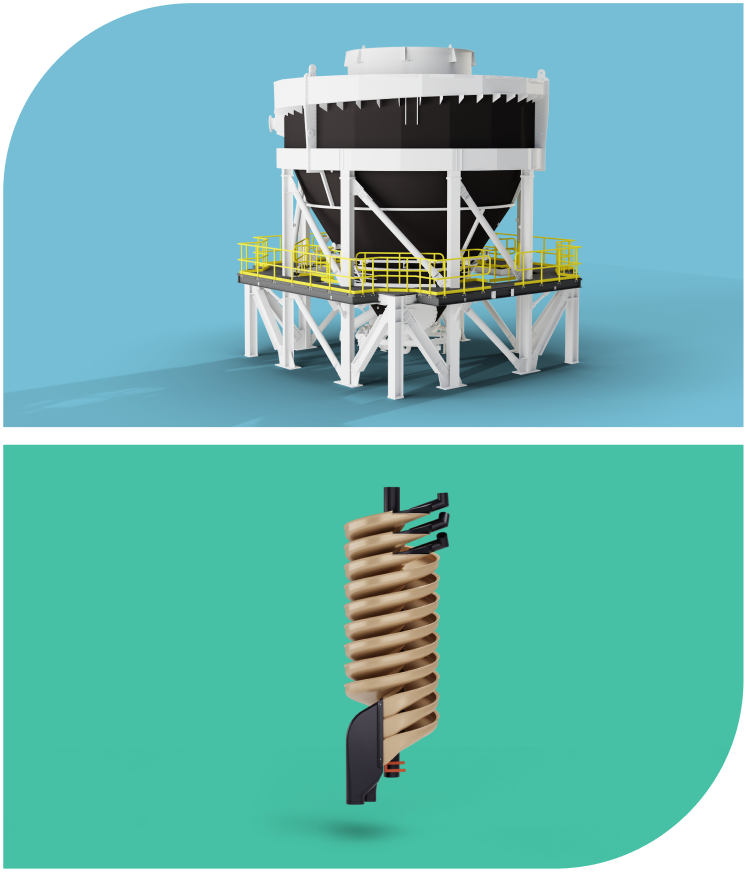

Equipment

Equipment

Proven technology

Our latest range of equipment built by decades of unmatched real world experience.

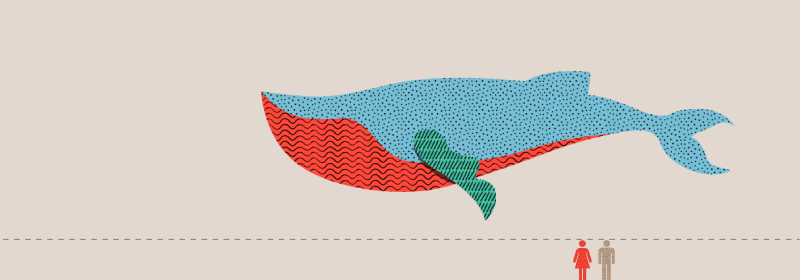

SizeMatters

Total Global Production of Mineral Sands

Total Weight: 3.278 (Mt)

3,278,000tonnes

21,853 Blue Whales

The equivalent of total mineral sands production.

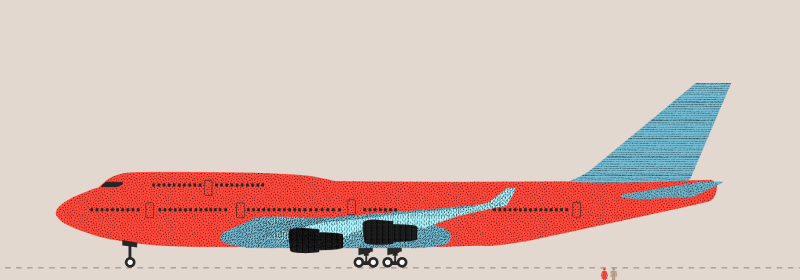

9,832 Boeing 747s

The equivalent of total mineral sands production.

Customers value our ongoing commitment to researching and developing new, innovative equipment designs that extract maximum value from mineral sands deposits.

– Etienne Raffaillac

Principal Metallurgist

What is Next

What is Next

Sustainable and Profitable Future

As we push the boundaries of mineral sands processing, we’re not just improving efficiency – we’re redefining responsible resource extraction. Our innovative solutions minimise land disturbance and water usage while maximising mineral recovery. This approach not only boosts profitability but also aligns with global sustainability goals. By partnering with us, you’re choosing a path that balances technological advancement with environmental stewardship, ensuring a brighter future for both industry and planet.

Brenda Van Rhyn

Regional Manager – Australia

Focus: Fine Minerals Recovery

I am a results-driven chemical engineer, passionate about delivering innovative equipment solutions that maximize revenue while minimizing costs.

The Expert

The Expert

ReachOut!

Ready to explore how our advanced technologies can revolutionise your operations? We’re here to help. Reach out to us today to learn more about how we can tailor our solutions to meet your specific needs and objectives.